Battery Life & Data Gaps: What 3PL Operators Must Check in Returnable Asset Tracking Solutions

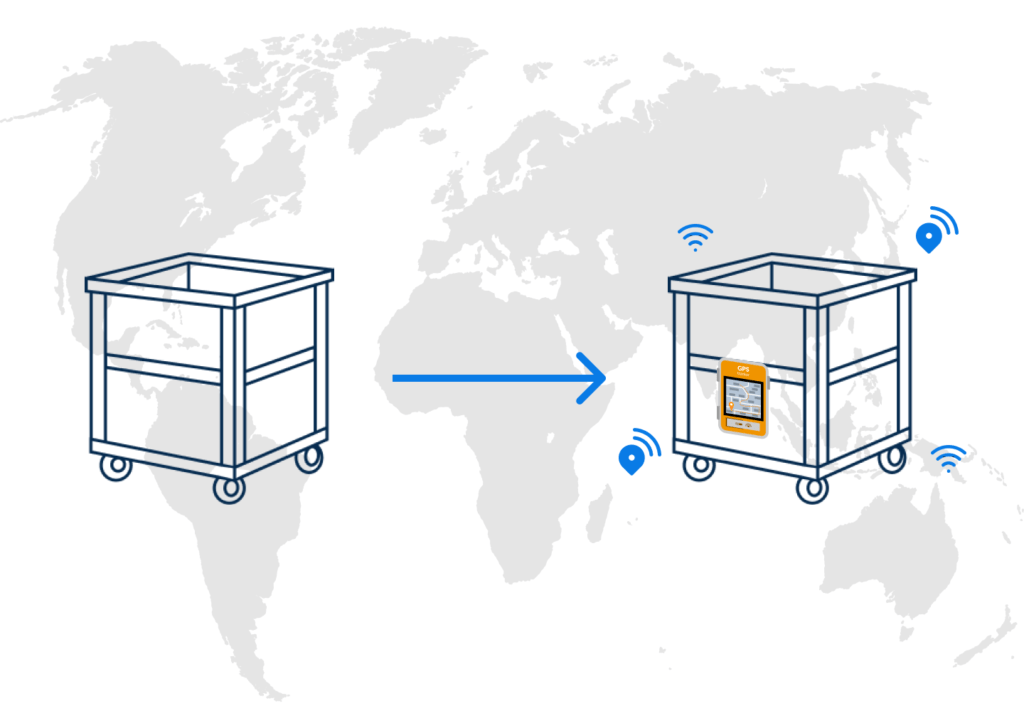

In 3PL logistics, the only thing that matters is the speed and the cost of delivery. For your asset tracking solutions, the most important part is to keep up with your speed and cost. So, what operational factors enable your asset tracking solutions to perform better? If you’re into 3PL and warehouse operations, you’d have surely heard or dealt with returnable asset tracking solutions. And you’d also know how ubiquitous the use of asset trackers is. […]

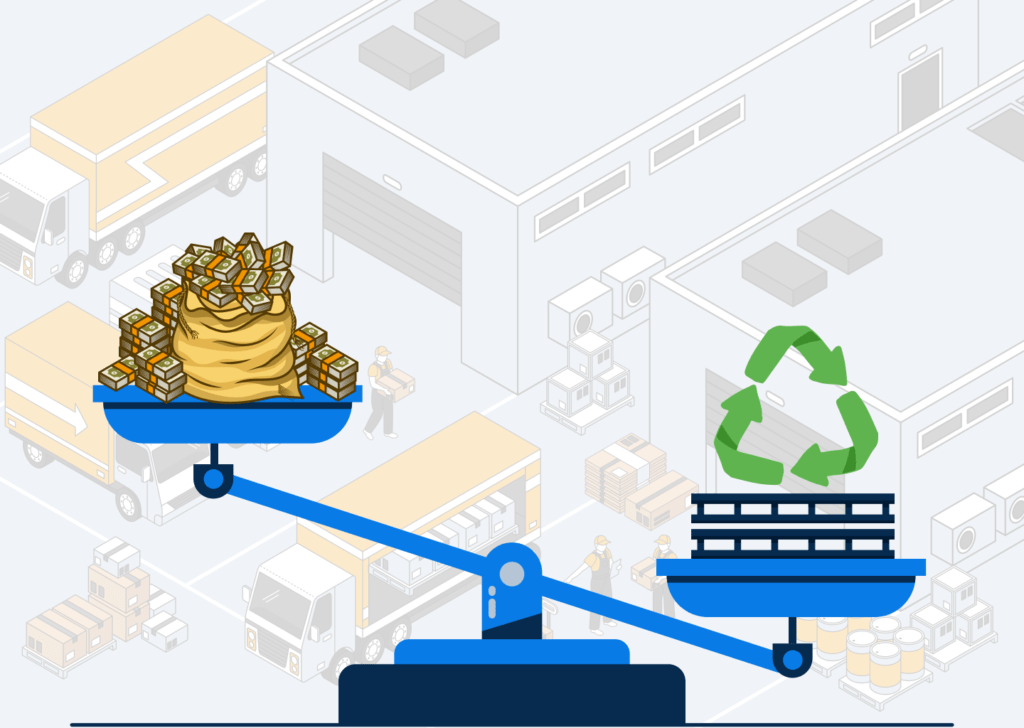

Plastic Pallets Leakage: A Case for Operational Efficiency and Sustainability Control

Plastic pallets were introduced into logistics networks as an upgrade for durability. They are stronger than wooden alternatives, reusable across multiple cycles, and central to modern pooling systems. Over time, however, many organizations have discovered that durability alone does not guarantee control. Plastic pallets do not disappear overnight; they leak gradually across transit routes, client facilities, subcontracted networks, and […]

5 Effective Solutions To Reduce Your Returnable Assets Costs

For many logistics and 3PL operations, returnable assets costs are treated as an annual inevitability. Each year, a portion of pallets, roll cages, and specialized carriers get replaced due to loss, damage, or unexplained shrinkage. And this expense goes out of your income statement without much analysis. In some networks, this replacement ratio reaches 30 to 40 percent of the total asset pool, translating […]

Manual Handling of Assets: A Financial Burden on Your Operations

Manual handling of assets is often associated with physical movement: lifting, scanning, loading, and unloading. In logistics operations, however, manual handling extends far beyond the warehouse floor. It includes spreadsheet-based reconciliation, partner confirmations over email, manual validation of geo location tracking data, and cross-checking GPS tracking reports against shipment schedules. Many logistics operators today invest in asset flow tracking […]

Better RoI on Returnable Assets Tracking: Integration with ERP/WMS/TMS

Returnable assets tracking platforms have evolved significantly. Location insights are now precise, alerts are configurable and customizable, and IoT in warehouse management environments now capture movement, dwell time, shock, and temperature events across asset pools. Yet, many operators still struggle to realize meaningful ROI from these systems. And the issue is not tracking accuracy. The real issue is the disconnect between […]

How Better Asset Visibility Reduces Plastic Pallets Theft and Silent Losses

“The pallets didn’t come back in time last night.” “We lost half of our pallets in transit last month. We’ll need to buy more.” “Where are these pallets? They’re showing as available in the inventory register.” If you work in warehousing, transport, or 3PL operations, you’ve heard versions of these conversations far too often. They come up during shift handovers, monthly […]

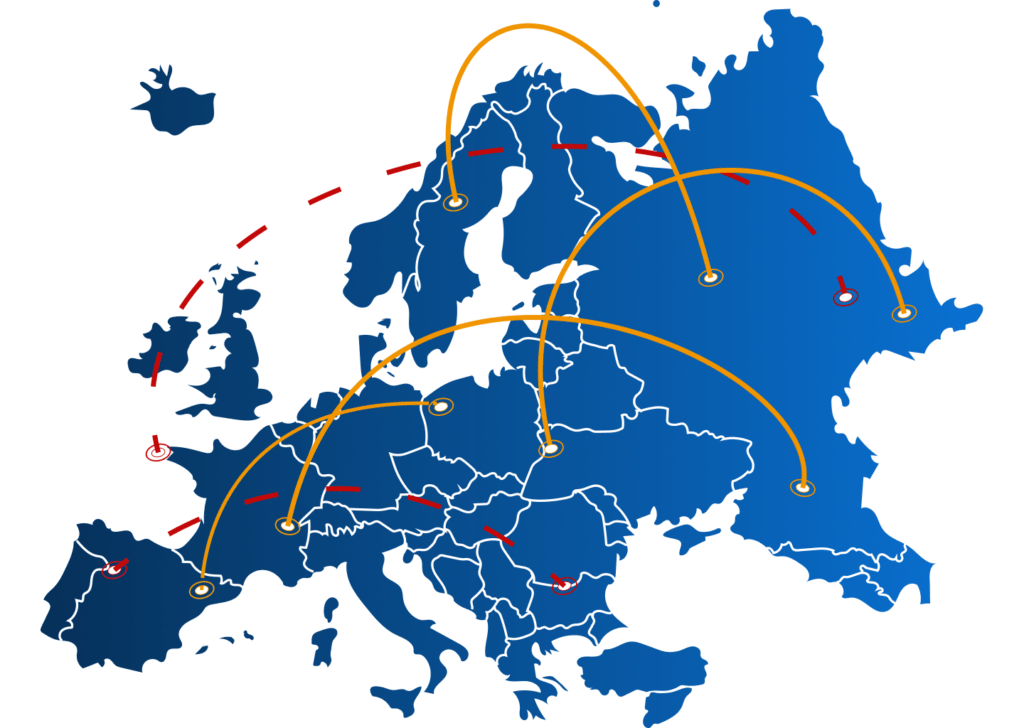

Expanding Returnable Assets Visibility for 3PL Logistics Network in Europe

The logistics networks in Europe is deeper and much more complex than ever before. Be it the logistics powerhouses of Germany and the Netherlands or the vital trade corridors of France and Spain, or the high-efficiency markets of the Nordics, the 3PL market is undergoing a tremendous change. As 3PL logistics network in these prominent European centers evolve to handle the massive volume of omnichannel returns and new circular […]

Asset Condition Monitoring in Time-Sensitive Supply Chains

Specialized carriers move goods that tolerate very little ambiguity. Unlike plastic pallets or roll cages, specialized carriers are designed to protect products from temperature excursions, humidity exposure, shock, vibration, and contamination. Pharmaceuticals, chemicals, and regulated materials need to arrive within defined temperature ranges, handling thresholds, and exposure limits. Thereby, the value of specialized carriers lies in their ability to preserve product integrity across long, multi-party supply chains. And […]

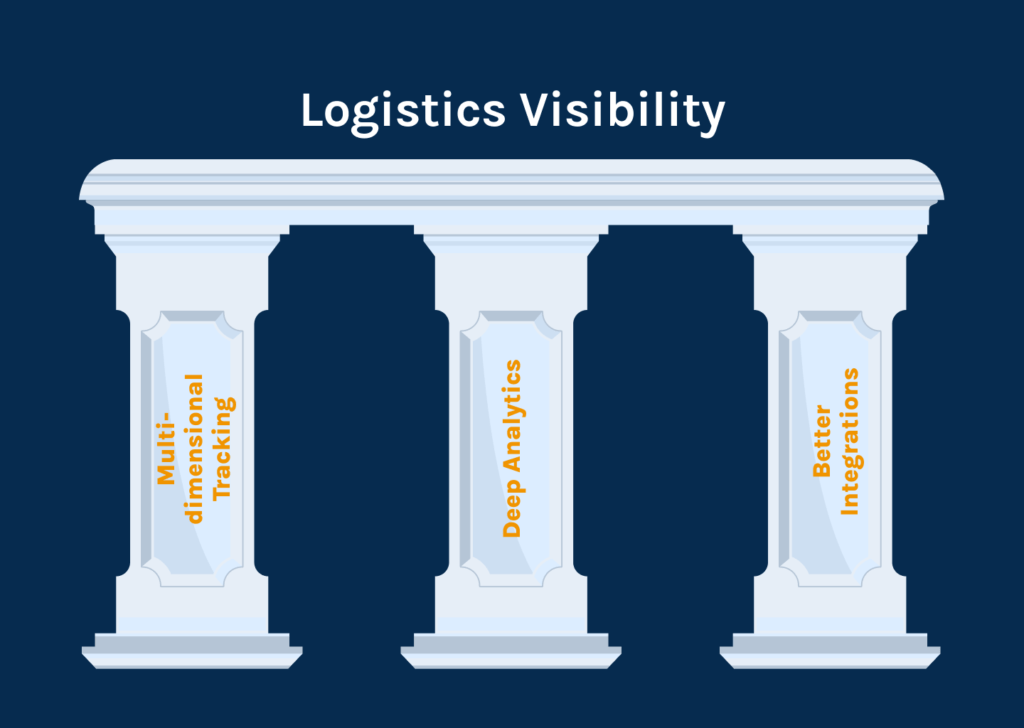

Strong Logistics Visibility Goes Beyond Vanilla Location Tracking for RTIs

If you work in logistics and constantly juggle delayed deliveries, missing returnable assets, and service pressures, this will feel familiar. Operating logistics networks today is hard enough. Doing it without full logistics visibility and while losing thousands of plastic pallets, roll cages, or reusable transport items every year makes it even harder. Assets go missing, shipments get delayed, and […]

Returnable Asset Management Without Visibility Creates Compliance Risk

Explore how sustainability regulations impose compliance risk for traditional returnable asset management and how Sensatrak helps you reduce that risk.