The promise of a circular economy is compelling: reducing waste, reusing resources, and closing the loop on materials that were once discarded. But moving from theory to practice requires a significant shift in how businesses manage and track their assets.

Circular supply chains need more than just a commitment to sustainability; they need data visibility, people and process alignment.

Returnable assets management and the data generated from such solutions is at the heart of this transformation. However, as much as companies have invested in these asset tracking systems, the data generated is still underutilized, often trapped in silos or disconnected from actionable processes.

Achieving true circularity in supply chains requires real-time data on the movement, condition, and availability of assets. In addition to the data, it also needs better visibility and the right set of people to make sense of the insights and take good decisions.

Whether it’s returnable pallets, containers, or shipping bins, businesses need continuous visibility to ensure assets are circulating efficiently, being reused effectively, and not accumulating as idle stock.

In the absence of this data & people management, companies cannot meet their sustainability goals or optimize the full lifecycle of their reusable assets.

This blog explores how modern asset monitoring solutions like SensaTrak provides the visibility & alignment necessary for circular supply chains to succeed.

We will discuss the importance of data integrations, visibility, process alignment, and how companies can maximize the value of their data to enhance returnable asset management and meet their sustainability targets.

The Need for More in Circular Supply Chains

The Need To Fix Data Integarions

Circular supply chains are dependent on the reuse of materials and assets. However, despite vast amounts of data being generated through asset tracking systems, many businesses still struggle to extract actionable insights. The core issue is not the absence of data, but its underutilization.

Companies are collecting information on their reusable assets, yet the challenge lies in how to turn that data into real-time, actionable decisions that optimize operations and reduce waste.

Many organizations are still using legacy systems or have not fully integrated their asset tracking technologies with operational processes and other supply chain data management applications. The integration between modern asset tracking technologies + platforms and the industry leading ERP/WMS/TMS applications (SAP NetSuite, Blue Yonder etc.) is usually a major challenge and keeps a lot of the data siloed and underutilized.

The lack of real-time insights often leads to inefficiencies such as underutilized assets, unnecessary procurement of new materials, and poor asset rotations, all of which hinder circularity goals.

For example, a company might be tracking asset movement but fail to connect that information with maintenance schedules or return cycles. This means that even though data is available, it’s not being used to its full potential.

Optimizing reusable assets management requires a system that integrates data from asset tracking and feeds it into operational workflows – ensuring that every decision, from asset rotation to maintenance scheduling, is based on accurate, real-time data.

Visibility Through Observability and AI-Driven Solutions

While data integration is the bedrock, the next level of circular supply chain success comes through observability and AI-driven solutions.

Observability provides real-time and extreme visibility, allowing businesses to not only see where assets are but also to track granular data points about their condition, usage patterns, and movement across multiple locations.

AI solutions enable businesses to predict when assets need maintenance or cleaning, ensuring that they remain operational for longer and don’t disrupt supply chain efficiency. For instance, predictive analytics can forecast when an asset is likely to require repair or replacement, reducing unexpected downtime and maintenance costs.

By integrating AI with real-time data, businesses can automatically adjust asset flows, ensuring that assets are rotated efficiently.

For example, if a certain returnable asset is underperforming in one part of the supply chain, AI can suggest redistributing it to another location where demand is higher. This ability to make real-time decisions significantly improves asset utilization and operational efficiency, which are the pillars of a sustainable circular supply chain.

Trained People for Data Utilization and Action

Technology alone can’t make circular supply chains successful – you need the expert personnel to interpret and act on the data.

With the increasing complexity of asset tracking systems, it’s essential that teams are equipped with the skills and knowledge to leverage the insights provided by these systems.

Training or providing the right kind of support to teams to understand and use data insights is crucial. Asset tracking systems generate massive amounts of data, but unless teams have the right kind of support to read and act on that data, it is ineffective.

For example, a logistics manager might have access to real-time data on returnable assets, but without the training and expert support to interpret that data, they may miss opportunities to optimize asset rotation or identify underused assets.

Moreover, cross-departmental training is essential. The operations team, logistics department, and maintenance crews need to understand how the asset management system works, how data is captured, and how they can use it to improve their workflows.

This holistic approach ensures that data doesn’t just stay on a dashboard; it’s actively used to drive efficiency and optimization across the business.

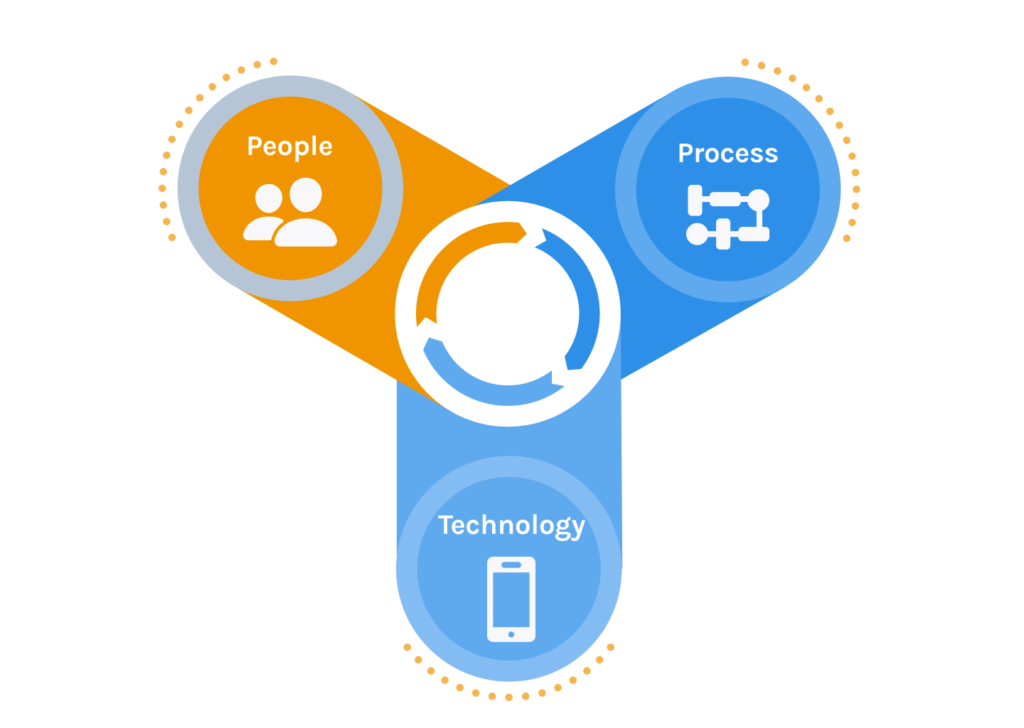

Process Alignment: Integrating People, Technology, and Data

Ultimately, the success of circular supply chains relies on the alignment of people, technology, and processes. It’s not enough to just have the best asset tracking tools or the most accurate data; businesses need to ensure that their people and processes are aligned to make the most out of these technologies.

Process alignment involves creating seamless workflows between different departments and functions, ensuring that the data captured by asset tracking systems is properly utilized across the supply chain.

That’s where a solution like SensaTrak comes in. Aligning extensive returnable asset management with 24*7 support, data integration and data insights to make sure the assets are managed wherever they are.

With such strong alignment of people, process, & technology, businesses can ensure that assets are always in the right place at the right time and are being used efficiently.

The best technology in the world is useless without proper alignment between technology and people who understand how to leverage it effectively.

Circularity in Action – Powered by Data

For circular supply chains to function, businesses must combine data visibility, AI-driven insights, and effective asset tracking with well-trained teams and streamlined processes. Data is the catalyst for circularity, but it’s the combination of people, processes, and technology that makes circular supply chains sustainable and efficient.

The future of circular supply chains depends on how well companies leverage their returnable assets management systems. By integrating data, training teams, and aligning processes, businesses can close the loop on circularity, meet sustainability goals, and enhance operational efficiency.