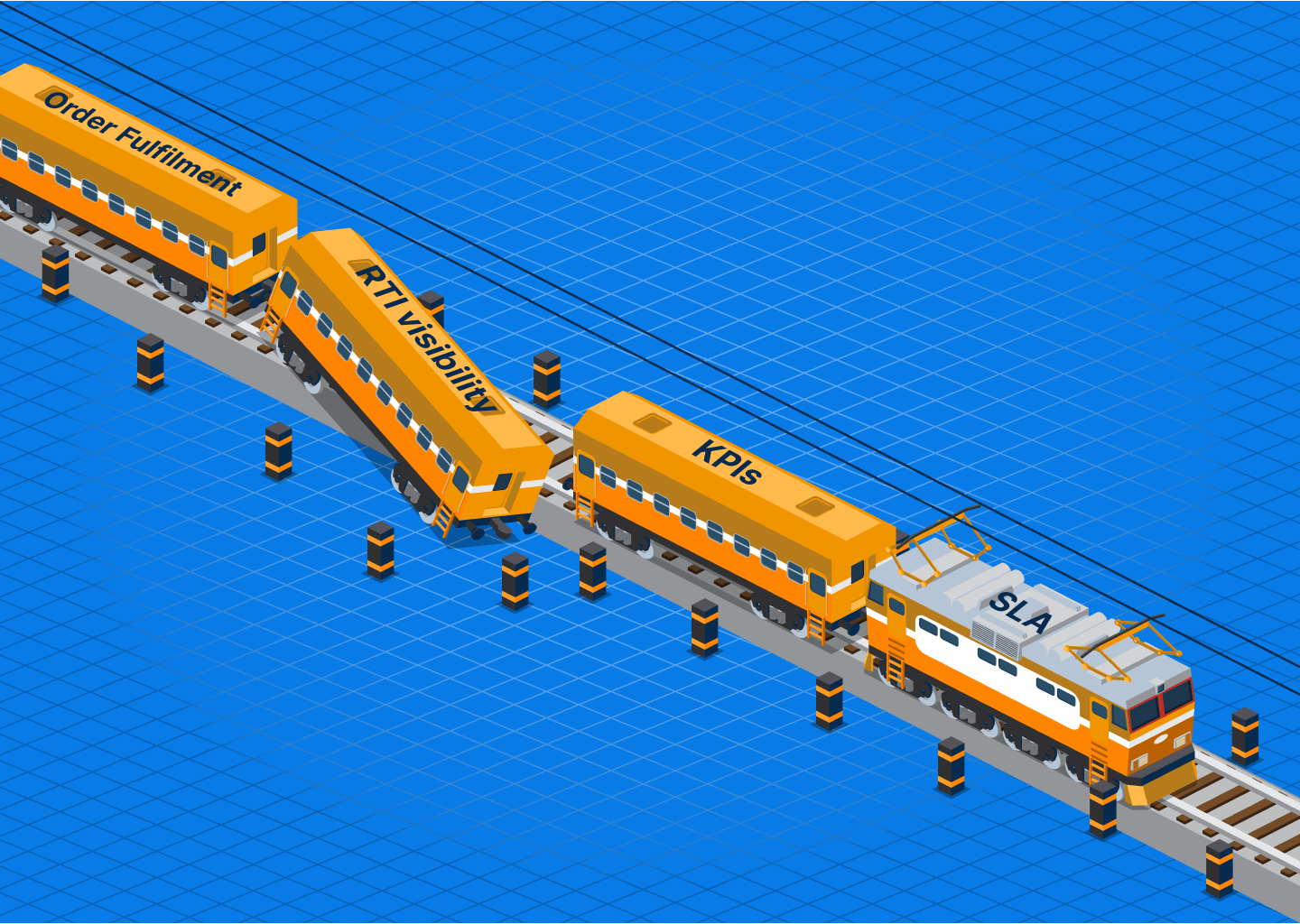

Service Level Agreements, or SLAs in logistics, are aimed at bringing structure and predictability to increasingly complex supply chains. They define expectations around delivery timelines, service quality, and penalties for non-performance. But SLA failures continue to rise, even in operations that appear well on paper and function.

A key reason lies in what most SLAs fail to account for: the assets that enable execution. In RTI logistics, pallets, roll cages, bins, and containers circulate continuously across warehouses, transport lanes, 3PL facilities, and customer sites. While shipments are tracked and measured, RTIs often operate outside formal SLA frameworks, treated as operational background rather than performance-critical assets.

Without continuous visibility into RTI fleets, logistics SLAs become difficult to enforce in real time, increasing the likelihood of service breaches as well as sustainability and compliance failures. Asset delays, extended dwell times, and damage accumulate silently at the RTI level, long before they surface as missed deliveries or inventory shortages.

Gartner’s research on the evolution of logistics KPI reporting reinforces this shift, noting that organizations are increasingly moving toward analytics- and AI-supported models that depend on consistent, contextual operational data rather than static summaries.

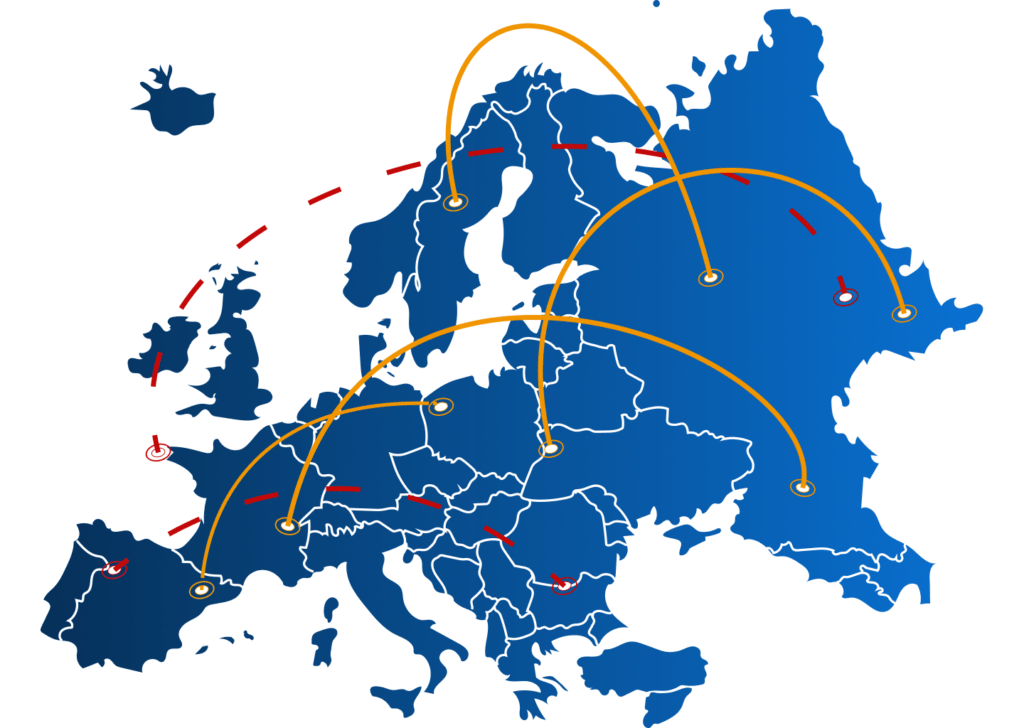

As supply chains grow more distributed and partner-driven, this RTI visibility gap widens. Supply chain SLAs increasingly span multiple organizations, systems, and handover points, yet RTI movement documentation across these boundaries remains poorly instrumented. This blog examines why SLA failures persist in logistics operations, how RTI management blind spots directly contribute to those failures, and what it takes to proactively solve the issue.

Where SLAs in Logistics Break Down Operationally

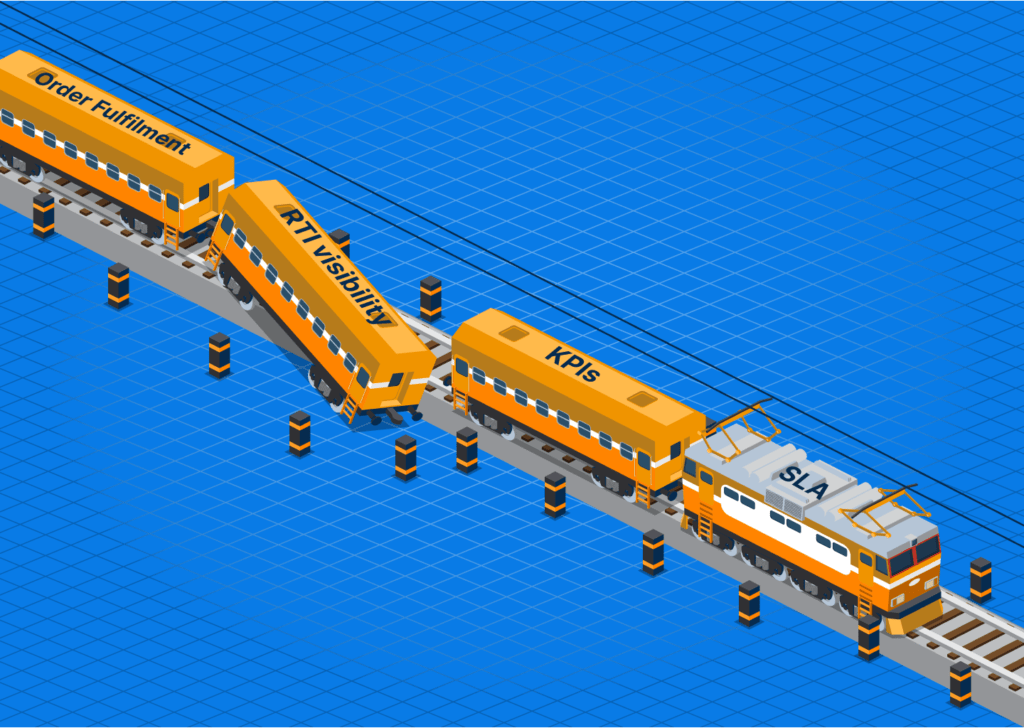

SLA management in logistics fails when RTI movement, dwell time, and condition are not visible in real time across the network. Most SLAs are outcome-focused, measuring delivery timeliness or order accuracy while overlooking the operational dependencies that make those outcomes repeatable.

This disconnect is especially visible in RTI logistics. Returnable assets move through multiple custody zones; as a result, shipments may meet SLA targets while RTIs remain stranded, damaged, or unavailable.

One of the most common contributors is unmanaged dwell time. RTIs frequently sit idle at customer locations, cross-docks, or partner facilities far longer than planned. When plastic pallets, roll cages, and specialized carriers are delayed, damaged, or lost, the impact is rarely immediate. Instead, the effects cascade across subsequent reuse cycles, constraining throughput and increasing variability. Over time, this creates structural instability: asset availability and reliability erode even as SLA reports appear stable.

Operationally, SLA enforcement is further weakened by fragmented systems. RTI data is often split across WMS, TMS, and ERP platforms, partner portals, and manual spreadsheets. Returnable asset condition uncertainty further compounds the problem. Damaged or non-compliant RTIs can halt receiving processes, trigger rehandling, or create safety risks.

Accountability gaps make recovery even harder. In multi-party networks, RTIs pass through several custodians, but responsibility for delays or losses is often unclear. Without shared, asset-level evidence, SLA enforcement becomes reactive and dispute-driven rather than preventive. These blind spots mean that SLA failure risk accumulates silently at the asset level long before it appears in shipment-level metrics.

Logistics teams monitor dozens of KPIs alongside SLA commitments, often without prioritization or automation. By the time a breach is detected, recovery options are limited, and costs have already been absorbed through emergency asset purchases, expedited handling, or service disruption.

Observability: The Missing Control Layer for Successful Logistics SLAs

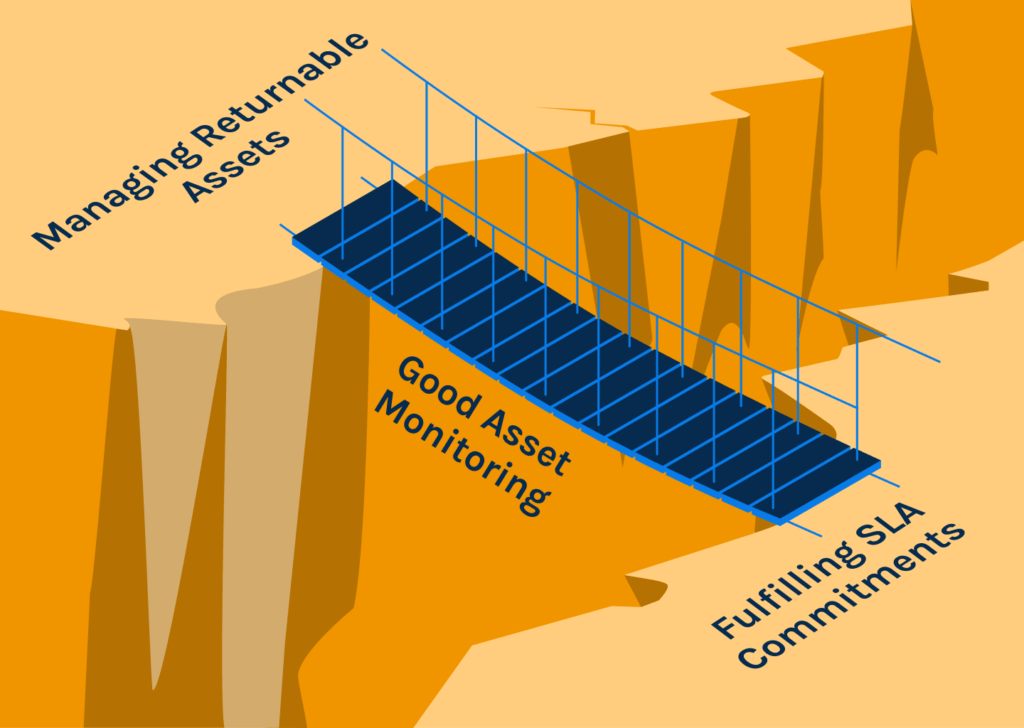

Observability changes existing models by shifting returnable asset management from retrospective measurement to continuous and proactive operational control. In practical terms, observability connects signals across systems and assets to explain why it happened and where risk is accumulating. For RTI logistics, this means correlating asset movement, dwell time, custody changes, and condition status across warehouses, transit lanes, and partner sites. When these signals are unified, SLA failure risks become visible long before thresholds are crossed.

This is the missing control layer for logistics SLA enforcement. Without observability, SLAs remain static targets applied to dynamic systems. With observability, SLAs become adaptive guardrails. For example, rising dwell times at a specific customer location can be detected early and flagged as an SLA risk, even if no breach has occurred yet. Repeated late returns from a 3PL site can surface as a systemic issue rather than isolated incidents. This allows teams to intervene while recovery is still possible.

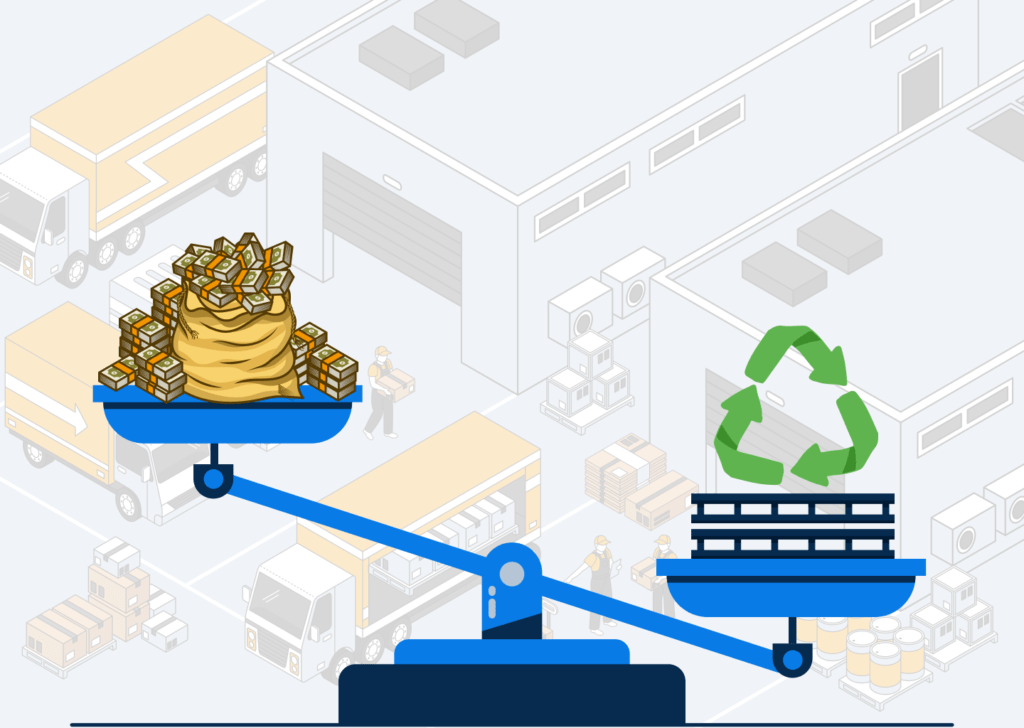

From a circular supply chain and compliance perspective, observability becomes essential rather than optional. Regulations such as the EU Packaging and Packaging Waste Regulation (PPWR) require organizations to demonstrate reuse, lifecycle performance, and loss reduction with verifiable data. This level of proof cannot be achieved through estimates or aggregated tracking metrics.

Observability also resolves one of the most persistent SLA management challenges: accountability. In multi-party supply chain SLA environments, disputes arise because each stakeholder sees only a partial version of events. An observability layer reconciles RTI data across systems, creating a shared operational truth. Chain of custody transitions, handover timestamps, and condition checks become auditable facts rather than negotiated claims. This shifts SLA enforcement from subjective escalation to evidence-based resolution.

Equally important, observability reduces operational noise. Instead of overwhelming teams with alerts, it prioritizes signals that threaten SLA performance. This enables focused action: reallocating assets, accelerating returns, triggering inspections, or adjusting partner workflows. Over time, these interventions stabilize RTI cycles, reduce variability, and improve SLA adherence without increasing manual oversight.

How SensaTrak Enables RTI Visibility That Augments Supply Chain SLAs

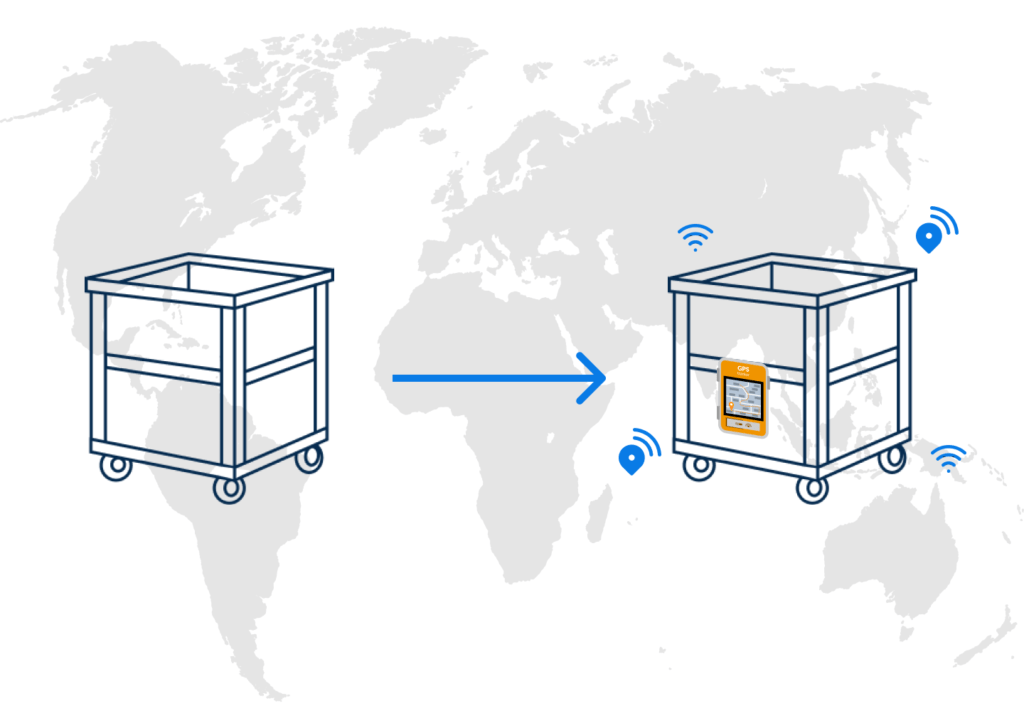

SLA-aware RTI management requires a system that continuously connects RTI movement, condition, and custody data to SLA thresholds and operational decision-making. SensaTrak is designed to act as that connective layer, bridging the gap between physical RTI flows and the contractual and operational commitments defined in logistics SLAs.

Our platform supports asset identification and monitoring across warehouses, yards, transit lanes, and partner sites using a combination of tag technologies and location signals. Every handover, dwell event, and movement milestone is captured as a structured data point, forming the baseline required for SLA-aware RTI management.

The difference lies in how your data is interpreted. SensaTrak’s observability layer correlates RTI events across WMS, TMS, ERP, and partner systems to detect early indicators of SLA risk. Instead of waiting for a breach, the platform highlights rising dwell times, delayed returns, and abnormal circulation patterns that threaten logistics SLA performance. This allows logistics teams to intervene while recovery is still possible, preserving service continuity, and is particularly critical for supply chain SLA governance in 3PL-heavy operations.

Beyond SLA enforcement, the same data foundation supports sustainability and cost control. Verified reuse cycles, condition tracking, and loss prevention reduce unnecessary RTI replacement and support reuse-driven sustainability targets. As a result, SLA compliance, RTI availability, and ESG objectives are reinforced by the same operational signals rather than managed as separate initiatives.

SLA failures in logistics are symptoms of unmanaged RTI flows, fragmented visibility, and delayed intervention. SensaTrak enables organizations to treat RTIs as SLA-governed assets, enforce performance in real time, and build logistics operations that are stable, accountable, and resilient by design.