Returnable assets are high-value, high-usage components of any logistics operation, and their financial and operational impact is substantial. Inefficiencies in asset utilization drive overinvestment in fleets, increase replacement costs, and create idle time that reduces overall productivity.

So, integrating artificial intelligence/AI in logistics seems to be the logical next step to improve returnable asset management. This McKinsey study from last year suggested that logistics organizations adopting a combination of real-time transportation visibility platforms (RTTVP), AI-based workflow automation, and generative AI-driven contextual communication can reduce operational waste caused by blind handoffs by 40% and cut fleet-related costs through predictive planning and proactive intervention.

Historically, automation has been a key driver in this industry. Machine learning (ML) and algorithmic decision-making have been applied in logistics for decades to optimize inventory, plan routes, and manage warehouse operations. But, unlike earlier automation, AI in returnable asset tracking can process vast volumes of real-time data to preempt supply chain disruptions, reduce idle assets, prevent waste, and enable faster decision-making. According to this Gartner survey, generative AI (GenAI) will account for 25% of all logistics KPI reporting by 2028.

However, successful integration requires strategic selection of systems that will benefit the most, rather than a blanket deployment across all operations. Targeted AI adoption ensures that returnable asset fleets are optimized efficiently without overwhelming existing workflows or IT infrastructure. And beyond efficiency, AI also supports sustainability and compliance objectives. By tracking reuse cycles, return compliance, and asset condition, AI in logistics ensures that organizations can meet regulatory requirements while minimizing material waste and extending asset lifecycles.

Ultimately, AI transforms returnable asset management from a reactive process into a data-driven, proactive system that optimizes both operational and environmental outcomes.

Implementation Challenges of AI in Returnable Asset Tracking

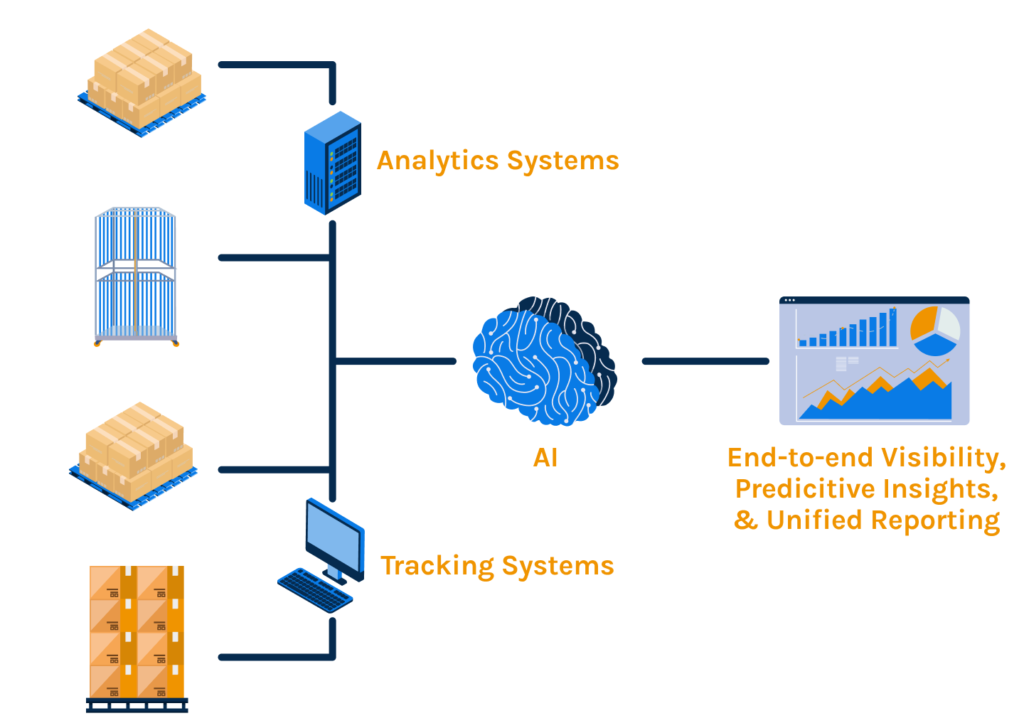

Implementing AI in returnable asset management offers substantial benefits, but logistics organizations often face technical, operational, and human challenges. One common issue is data fragmentation. Returnable asset data is typically spread across WMS, TMS, ERP, and IoT tracking devices. AI relies on high-quality, integrated data streams; without system integration, models cannot generate accurate predictive insights or actionable recommendations. Data silos and misalignment also lead to AI model degradation over time.

Another challenge is legacy infrastructure and compatibility. Many mid-sized logistics operations use older software or proprietary platforms that do not easily interface with modern AI systems. Without middleware or API standardization, data flow is inconsistent, causing delays in analysis and limiting AI’s effectiveness. Organizations must carefully identify which systems will benefit most from AI and prioritize integration instead of attempting a blanket implementation, which can overwhelm operations and increase costs.

Finally, human expertise and change management play a critical role. AI implementation requires skilled personnel who understand both supply chain processes and AI outputs. Without proper training, teams may misinterpret insights, underutilize predictive recommendations, or fail to maintain governance protocols. Successful adoption combines technology, process alignment, and expert guidance, ensuring AI insights translate into operational efficiency, better asset utilization, and measurable compliance and sustainability outcomes.

How AI in Logistics Will Transform Future Returnable Asset Management

As mentioned earlier, machine learning has been widely used in logistics and supply chains to analyze historical and current data to forecast idle assets, identify items at risk of damage, and detect partner or route behaviors that may cause delays, helping logistics teams optimize fleet allocation and reduce replacement costs. However, ML systems primarily focused on specific tasks rather than supply chain observability. AI in returnable asset tracking takes this further by integrating multi-source data and enabling real-time, predictive insights across the entire asset lifecycle.

Computer vision (systems interpret and understand visual information from the environment, such as images and videos), trackers, and IoT sensors complement AI/ML systems by monitoring asset condition and environmental factors, detecting damage, misalignment, or temperature deviations, and providing insights into automated systems. Predictive analytics can further enhance returnable asset visibility, estimating maintenance needs, lifecycle degradation, and underutilization to right-size fleets, reduce waste, and support ESG reporting.

Logistics platforms, like SensaTrak, also use event correlation and natural language processing (NLP) to integrate unstructured data from multiple systems, such as WMS, TMS, ERP, and partner reports. This allows automatic reconciliation of asset movements, anomaly detection, and optimized routing, providing logistics teams with a unified view of their entire operation.

Combined with AI, these technologies create a holistic, intelligent system that improves returnable asset utilization, ensures compliance, and drives operational and sustainability performance.

How SensaTrak Applies AI to Returnable Asset Tracking

SensaTrak leverages AI in logistics to turn fragmented telemetry into actionable intelligence, enabling logistics teams to optimize the lifecycle of pallets, roll cages, and containers. Our platform integrates sensors, trackers, and subsystems into a unified data layer, feeding an AI-driven analytics engine that provides predictive, real-time insights across every stage of the returnable asset lifecycle.

Predictive analytics helps you identify inefficiencies in reverse logistics and partner networks, highlighting overdue returns, idle assets, and bottlenecks in asset flow. Our platform-first approach simplifies compliance by logging reuse cycles, condition checks, and custody events into a single, audit-ready dataset. Deployed in a modular manner, SensaTrak’s returnable asset management solutions scale as your operations evolve, supported by experts who tune each environment for accuracy and resilience. To get a preview of our process, contact us here.