Every active logistics operation today is dependent on a dizzying number of processes and subsystems running simultaneously. ERP for finance and procurement, WMS for warehousing, TMS for transport, multiple third-party services, etc. In theory, logistics integration should ensure each of these systems should talk to one another, exchanging data seamlessly across departments and partners, but in reality, they are often misconfigured, leading to data silos, which cause daily disruptions.

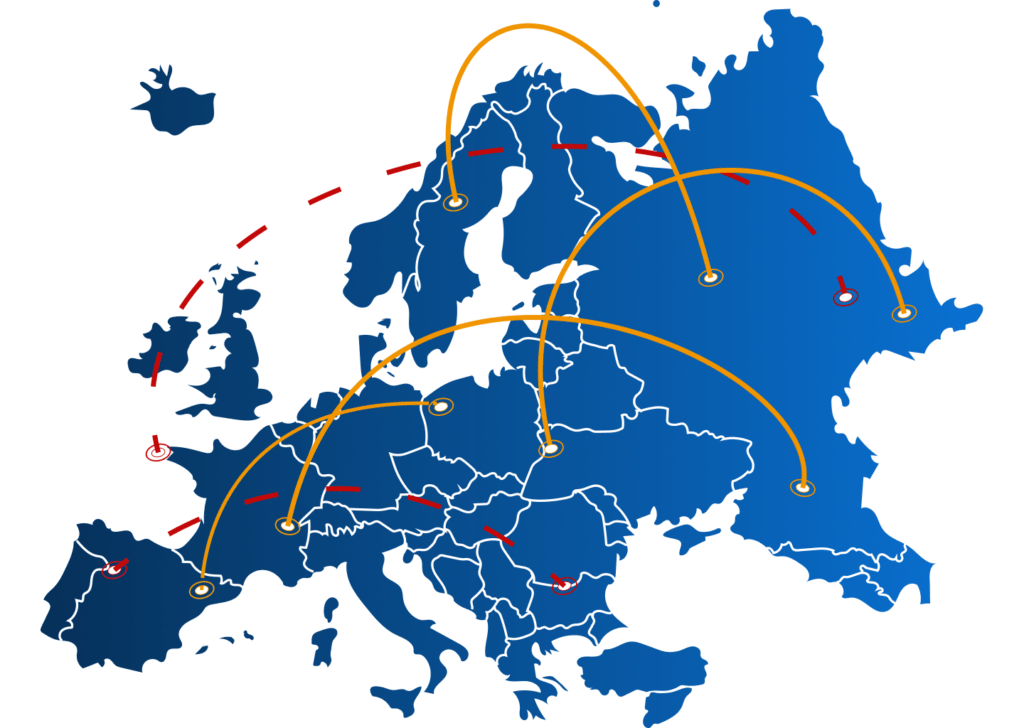

A global survey from 2020 showed that only 6% of supply chain companies had managed to achieve end-to-end visibility. In the context of returnable asset tracking, this disconnect shows up in familiar ways: lost pallets, roll cages, and containers that never check back in; mismatched counts between WMS and tracking systems; or carrier data that doesn’t sync with ERP cost records.

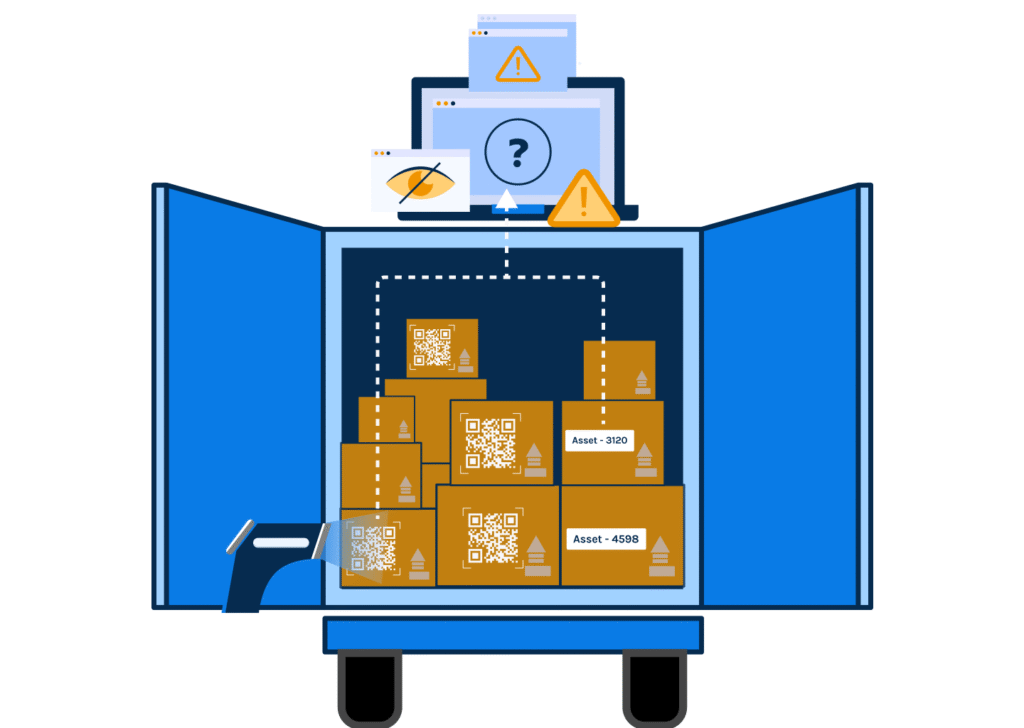

Without logistics integration, businesses capture fragmented visibility, where one system shows an asset available while another still flags it as in transit. This misalignment causes both underutilization of reusable carriers and overinvestment in RLC/RTI fleets; teams buy more assets simply to compensate for the uncertainty.

Disconnected systems aren’t new, but they’re a primary concern now as more supply chain businesses adopt tracking technologies and analytics without ensuring that the data flows correctly across their ecosystem. On-ground logistics teams face a deeper visibility gap caused by incomplete data synchronization and limited integration expertise. EY reports that 22% of supply chain executives still communicate with suppliers using plain old tools like spreadsheets and email, while 42% have begun using digital and cloud-based solutions.

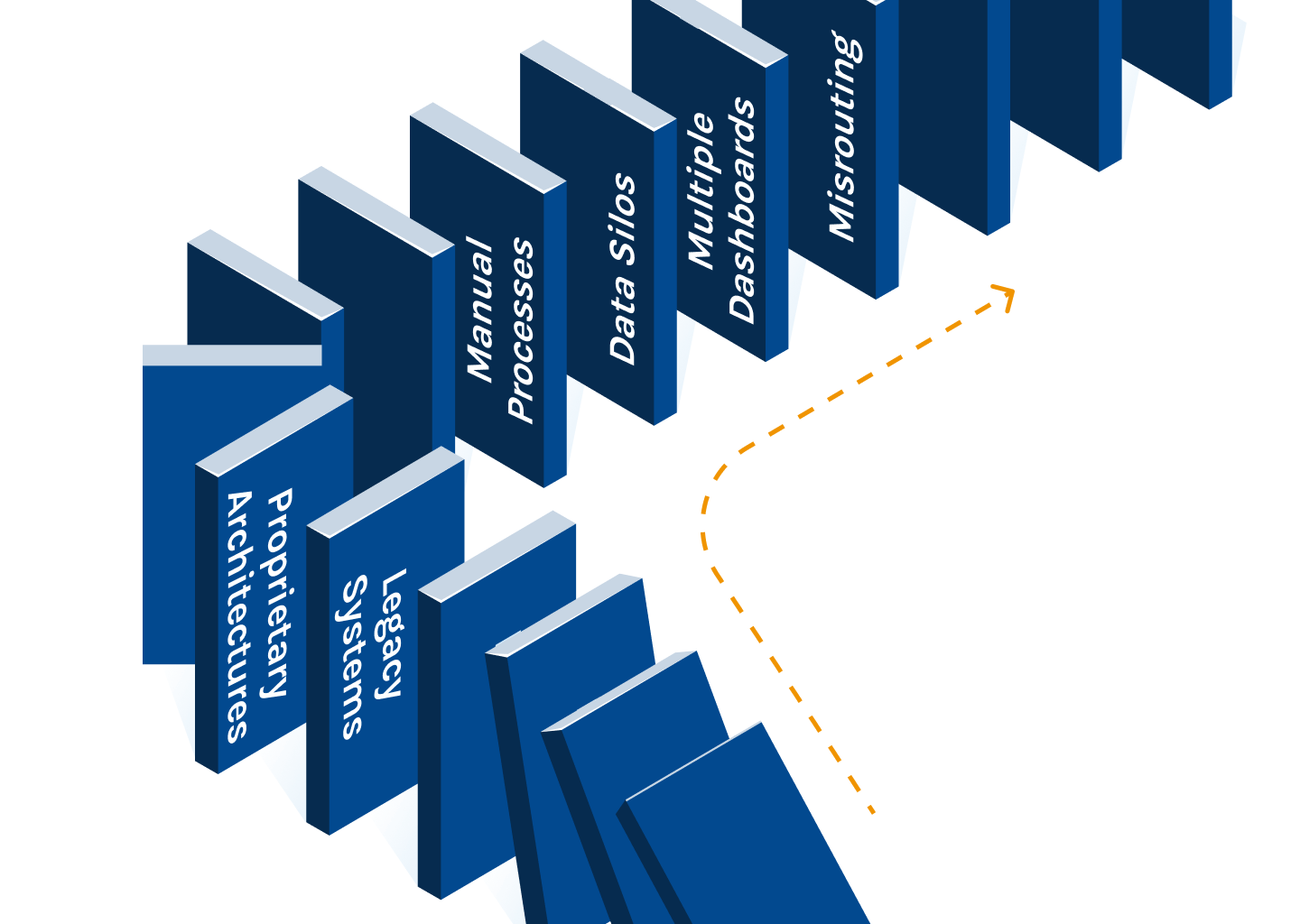

Each logistics integration failure compounds inefficiency, creating more manual work, slower reconciliation, and less reliable insights. Sensors collect returnable asset data, systems record chain of custody transfers, dashboards provide an overview of fleet usage, etc., but without the proper integrations, all that data remains isolated, preventing true observability across the supply chain operation.

In this blog, we’ll explore the real-world integration challenges plaguing returnable asset tracking solutions and how organizations can move toward full-system interoperability with the help of the right technologies, predictive analytics, and expert-led data alignment.

Logistics Integration Challenges & the Human Gap in Logistics Today

Real-time visibility in logistics depends on seamless data flow between systems, but in most organizations, that flow is blocked long before it reaches the decision-making layer. Integration issues come from cumulative friction between legacy systems, 3PL services, incompatible configurations, manual processes, and data misalignment. Over time, this erodes confidence in the returnable asset management solution, which silently inflates costs, prolongs turnaround cycles, and weakens compliance posture.

Legacy Systems & Proprietary Architectures

A lot of organizations operating in logistics still rely on ERP and WMS platforms built on outdated frameworks or closed architectures. These systems often lack modern APIs or real-time data connectors, making it difficult for IoT-based tracking tools to share telemetry. A lot of supply chain systems still depend on custom-built or outdated technology that cannot interface with cloud-native platforms. When returnable asset tracking data can’t integrate directly with these systems, operators lose sight of where assets actually are versus where the system thinks they are.

Data Silos & Vendor Fragmentation

Fragmented data remains one of the most persistent asset management issues, often leading to miscounts, manual reconciliation, and decision delays. Without standardized data models and a unified approach, different systems define and interpret asset status differently, leading to duplication and inconsistency. Each logistics stack typically includes multiple vendors: one for network connectivity, another for returnable asset tracking software, and still others for analytics. Each vendor updates its software differently, uses distinct data schemas, and maintains separate security protocols. When synchronization fails between layers, teams are left with data gaps that undermine trust in the system.

Limited Standardization & Misalignment Across Systems

Logistics integration is about timing, ownership, and process alignment. If operations, IT, and logistics teams don’t share an agreed protocol for system updates, the integration will drift. There’s little to no universal agreement on communication protocols or data structures for returnable assets, and over time small mismatches in data synchronization create big mismatches in physical operations. For example, some systems rely on MQTT or HTTP APIs, others on CSV or flat-file exchanges. This lack of standardized data exchange formats is one of the primary causes of integration failure in logistics visibility projects; it forces logistics teams to rely on custom connectors, which are fragile, expensive, and difficult to maintain.

The Human Gap in System Integration for Supply Chains

Even with advanced tracking tools and analytics, many logistics operations fail to achieve seamless visibility because of the expertise it takes to integrate and sustain it. The logistics integration challenge also extends to process and redundancy design. Gartner’s 2024 Supply Chain Talent Report identifies demographic shifts, talent acquisition competition, and changing work preferences as some of the hiring hurdles, particularly in mid-sized logistics and warehousing organizations. Without specialists who understand how digital systems interact with operational processes, disruptions spiral out of control. Over time, teams stop trusting the dashboards and revert to manual methods, reversing the intended efficiency gains.

Building the Foundation for System Interoperability

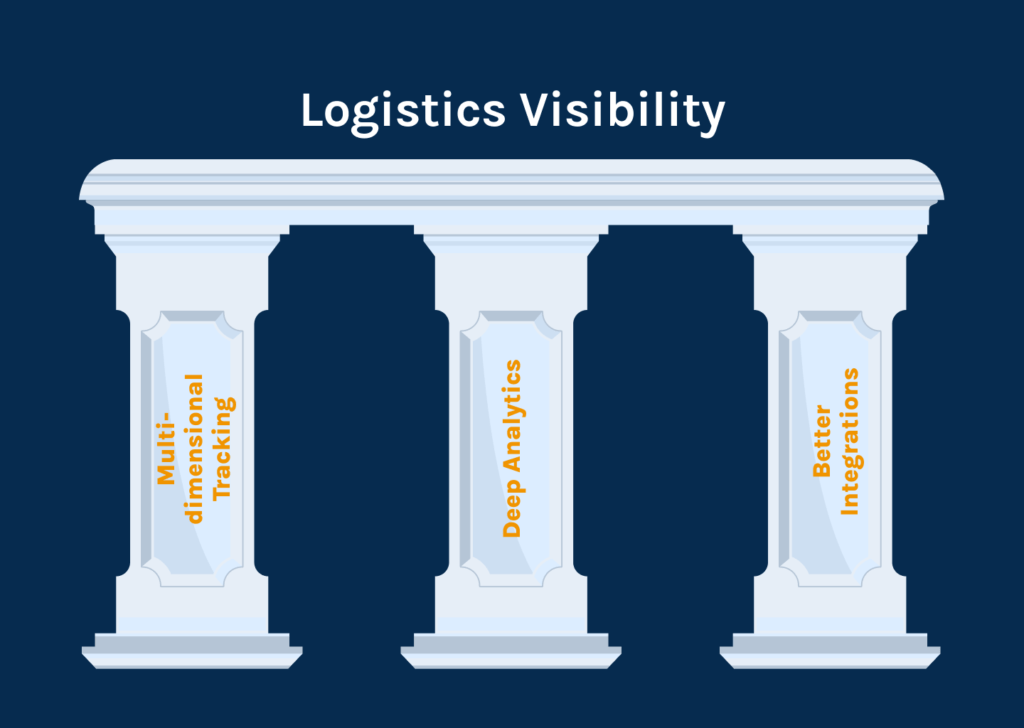

Disconnected systems always show initial symptoms of minor data friction, which scales into returnable asset fleet overinvestment, lost time, audit gaps, and sustainability setbacks. True interoperability requires consistent data models, open connectivity, and operational alignment that ensures every asset-related event is captured once and understood everywhere. It demands technical alignment, data governance, and incremental adoption supported by the right architecture and expertise.

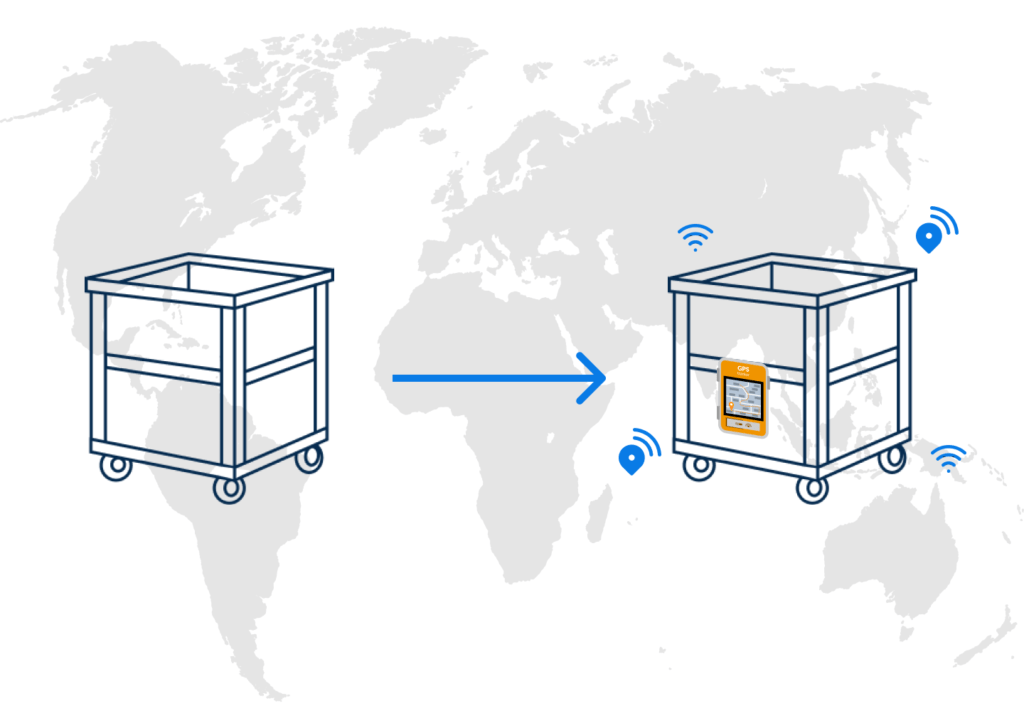

For instance, systems built on proprietary formats limit scalability, while open APIs and standardized communication protocols (such as REST, MQTT, or GS1 EPCIS for asset data) make interoperability possible. For returnable asset tracking, this means BLE, RFID, and GPS telemetry should map to a shared asset schema: ID, location, condition, timestamp, and custody.

Another thing to note is that even when systems integrate, visibility can remain fragmented if each one retains its own metrics, alerts, and logs. Large-scale logistics integration projects often fail due to overreach, so it’s better to start with synchronizing tracking and warehouse management data to fix the biggest visibility gaps. Then expand to ERP for financial reconciliation and to TMS for transport cycle optimization. This staged approach minimizes disruption, allows learning between phases, and delivers measurable value at each step.

Attention should also be paid to establishing data governance, which ensures that data flowing into ESG, compliance, and audit systems remains trustworthy for reporting reuse cycles and carbon reduction metrics tied to their returnable assets. A centralized logistics observability platform, like SensaTrak, aggregates all that information, correlating asset data, network events, and system health through a unified approach. Once standardized, any system can interpret and act on that data, enabling end-to-end visibility.

Finally, interoperability must be maintained by people, not just platforms. Upskilling in-house teams to understand API management, data observability, and cross-system dependencies reduces long-term reliance on external integrators. Building this internal competence ensures that integration evolves with business needs.

How SensaTrak Solves the Logistics Integration Problem

SensaTrak bridges the visibility gap between tracking and operations through a unified approach. Our platform continuously validates and reconciles data across systems to maintain integrity. Deployed in a modular manner, SensaTrak’s returnable asset management solutions scale as operations evolve, supported by experts who tune each environment for accuracy and resilience. Contact us here.