The logistics industry has long struggled with fragmented visibility across its asset fleet. A survey from 2020 showed that only 6% of supply chain companies had managed to achieve end-to-end visibility. Proper utilization of returnable assets depends on how visible they are on your systems while they’re in transit.

This is where observability in logistics and supply chains can help better manage returnable assets like pallets, containers, or roll cages.

Observability refers to the ability to track, measure, and understand a system’s internal operations by analyzing its external outputs.

Returnable asset tracking has typically remained limited to monitoring and static alerting systems. While technology offers various tracking tools and systems, many logistics teams still face significant gaps in leveraging the telemetry their RTP/RTI fleets generate. This lack of observability in logistics creates hidden costs due to lost and underutilized returnable assets, which also compounds compliance issues.

At the heart of the problem is not just visibility but the lack of integration between multiple systems and technologies being used within a logistics operation. Without a unified observability framework, companies are left with incomplete data that cannot drive actionable insights.

This is where observability in logistics matters: it’s not enough to know an asset is in transit; you need to understand its condition, location, and lifecycle status at every stage of the process. It means you can access, interpret, and act on all the data generated by your returnable asset tracking systems in real time. That’s what allows logistics teams to become proactive with how they manage their returnable asset fleets.

In this blog, we’ll explore why observability in logistics is crucial for managing the returnable asset lifecycle, how it drives efficiency, and why it’s essential for compliance and sustainability in today’s supply chain landscape. We’ll also highlight how a unified, platform-first approach enables organizations to overcome the fragmented, siloed systems and unlock the true value of their returnable asset fleets.

Why Observability Matters for Returnable Asset Tracking & Management

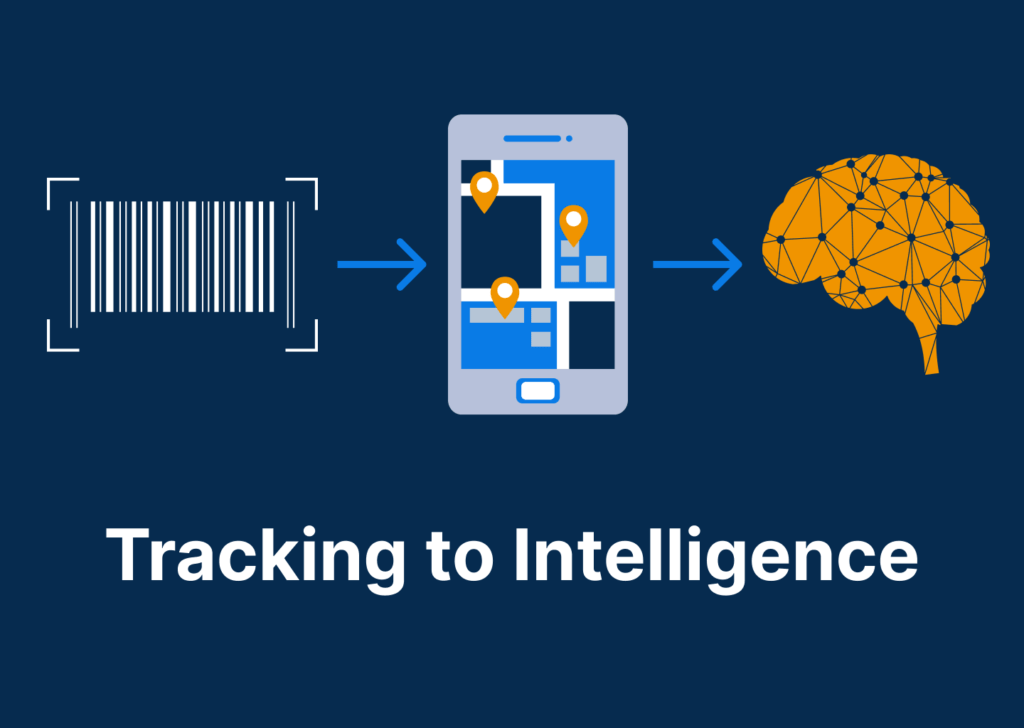

Unlike the prevalent visibility measures logistics teams implement, which focus solely on tracking assets from point A to point B, observability integrates data from multiple sources.

From returnable asset tracking technologies (RFID, BLE, GPS) to maintenance logs, condition reports, and external systems (ERP, WMS, TMS). This creates a comprehensive, 360-degree view of the asset lifecycle, enabling teams to anticipate problems, optimize workflows, and make informed decisions faster.

This level of insight is essential in the management of returnable assets. For example, a fleet of plastic pallets is a network of high-value, high-use assets that require continuous monitoring. Without observability, logistics teams are unable to track these key metrics, leading to underutilized assets, overstocked inventories, and increased operating costs.

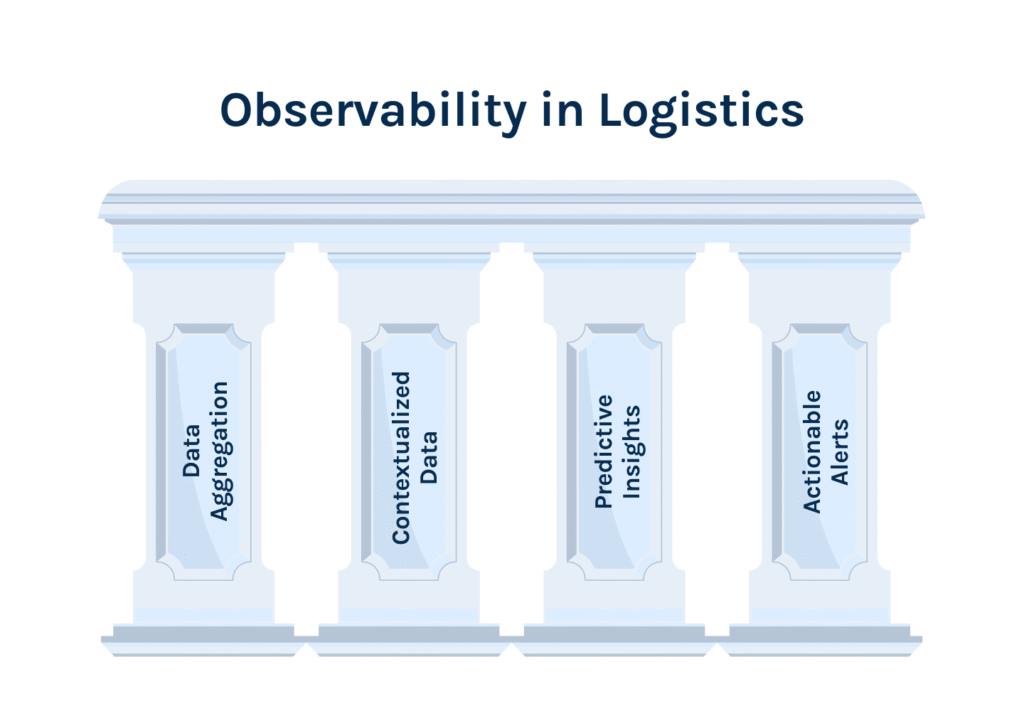

The Core of Observability in Logistics

- Data Aggregation

Real-time location tracking, asset condition monitoring, and movement data are aggregated into a centralized platform.

- Contextualized Data

The data isn’t just raw; it’s contextualized, allowing logistics teams to know not just where an asset is, but also its state (damaged, overdue, idle) and any potential issues.

- Predictive Insights

Observability platforms use analytics engines to turn historical and real-time data into predictive insights, identifying potential failures, underutilized assets, or deviations from normal asset cycles.

- Actionable Alerts

Instead of static dashboards, observability provides real-time notifications when assets are at risk of being lost, idle too long, or failing to meet operational benchmarks.

Observability in logistics ensures that returnable asset management goes beyond simply knowing where things are and helps teams understand how their reusable carriers perform, how they impact the broader supply chain, and how to optimize their use across every stage of the lifecycle.

Why Observability Matters for Returnable Asset Lifecycle

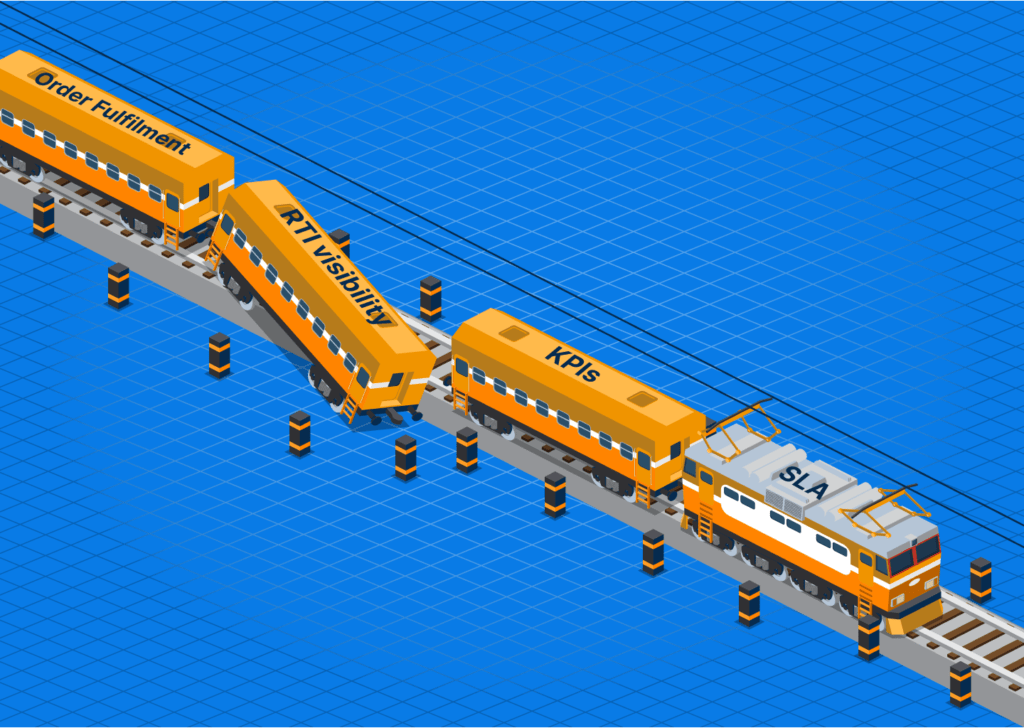

Achieving end-to-end visibility for returnable assets is about ensuring that the right data flows seamlessly across your entire system, is actionable in real-time, and drives decisions that optimize asset performance. A successful observability strategy for returnable asset management connects operational, asset, and system data into a cohesive whole.

Data Integration Across Systems

Real-time tracking data is only valuable if it integrates smoothly with the existing supply chain systems.

A siloed approach where asset data is locked in one system (WMS, TMS, or ERP) severely limits visibility and decision-making capabilities. By streamlining data flow between these systems, observability platforms reduce manual data entry errors and synchronize asset status across multiple teams and departments.

According to this McKinsey article, 40% of blind handoff costs can be reduced through better integration, AI-based workflow automation, and data alignment across systems.

Predictive Analytics & Insight Generation

Merely knowing where assets are located isn’t enough. Predictive analytics is a game-changer for logistics operations and returnable asset lifecycle. When tracking data is analyzed in real time, teams can gain actionable insights into potential issues before they arise.

For example, AI/ML models can forecast when a plastic pallet is likely to fail or require maintenance based on factors like temperature, shock data, and cycle history.

This proactive approach helps reduce downtime and increases the lifecycle of assets. Predictive insights also help optimize asset returns by forecasting when an asset will be idle, thus improving asset rotation, reducing unnecessary purchases, and leading to overall fleet utilization improvements.

Unified Data Platform for Asset Lifecycle Management

A key feature of observability systems is the centralized platform that consolidates data from all sources and technologies into a single, unified dashboard. This platform serves as the central hub for asset tracking, predictive analysis, and real-time monitoring.

- Lifecycle Tracking

From the moment a pallet is manufactured to its return and reuse, observability systems track every stage of its lifecycle, ensuring full traceability for compliance and audit purposes.

- Utilization Metrics

The platform provides visibility into asset performance, highlighting which assets are underperforming or idle, and allows teams to optimize fleet size, return rates, and maintenance schedules accordingly.

SensaTrak’s unified approach to returnable asset tracking and predictive analytics provides a holistic view of assets, from movement data and condition tracking to financial metrics, compliance reports, and sustainability insights. This 360-degree visibility enables logistics teams to reduce waste, cut unnecessary purchases, and enhance sustainability efforts.

Improved Compliance & Sustainability Reporting

Returnable asset management solutions are increasingly being held to stringent regulatory frameworks that require evidence of sustainability, reuse, and lifecycle management. Frameworks like the EU Packaging and Packaging Waste Regulation (PPWR) and Extended Producer Responsibility (EPR) regulations demand that companies prove the reuse of their returnable packaging and track assets through every stage of the supply chain.

For example, a logistics platform that automatically logs returnable asset movements and condition updates provides a data-driven audit trail that helps logistics teams meet sustainability objectives without manual tracking.

Data-Driven Insights for Continuous Improvement

The power of observability lies in its ability to provide data-driven insights that feed continuous improvement efforts. As assets are tracked across their entire lifecycle, performance data is aggregated and analyzed to identify patterns, inefficiencies, and areas for improvement.

- Utilization analysis can highlight underperforming assets that are unnecessarily taking up space in warehouses or reverse logistics chains.

- Maintenance trends show when and where pallets or containers are most likely to need repair, allowing teams to preemptively schedule maintenance and avoid costly downtime.

By leveraging these insights, logistics teams can fine-tune their asset management strategies, optimizing supply chain performance and reducing operational risks.

How SensaTrak Enables Observability for Returnable Assets

Even with compatible systems, successful observability depends on specialized expertise. ERP, WMS, TMS, and 3PL processes need alignment with asset tracking technologies. A lack of personnel with integration and observability skills leads to misconfigurations, partial data feeds, and inefficient dashboards. These misalignments degrade the reliability of lifecycle data, directly affecting decision-making, fleet optimization, and sustainability reporting.

SensaTrak delivers continuous, end-to-end visibility across the returnable asset lifecycle by combining multi-technology tracking, unified data integration, analytics, and expert-guided implementation. Our predictive analytics platform translates raw data into actionable insights and predictive intelligence.

Expert-guided integration ensures both technical alignment and operational governance, transforming returnable asset management from reactive monitoring into proactive lifecycle optimization.

If you’re looking for a solution that unifies RTI tracking, predictive analytics, and AI-driven workflow automation for your logistics operation, reach out to us here.