“The pallets didn’t come back in time last night.”

“We lost half of our pallets in transit last month. We’ll need to buy more.”

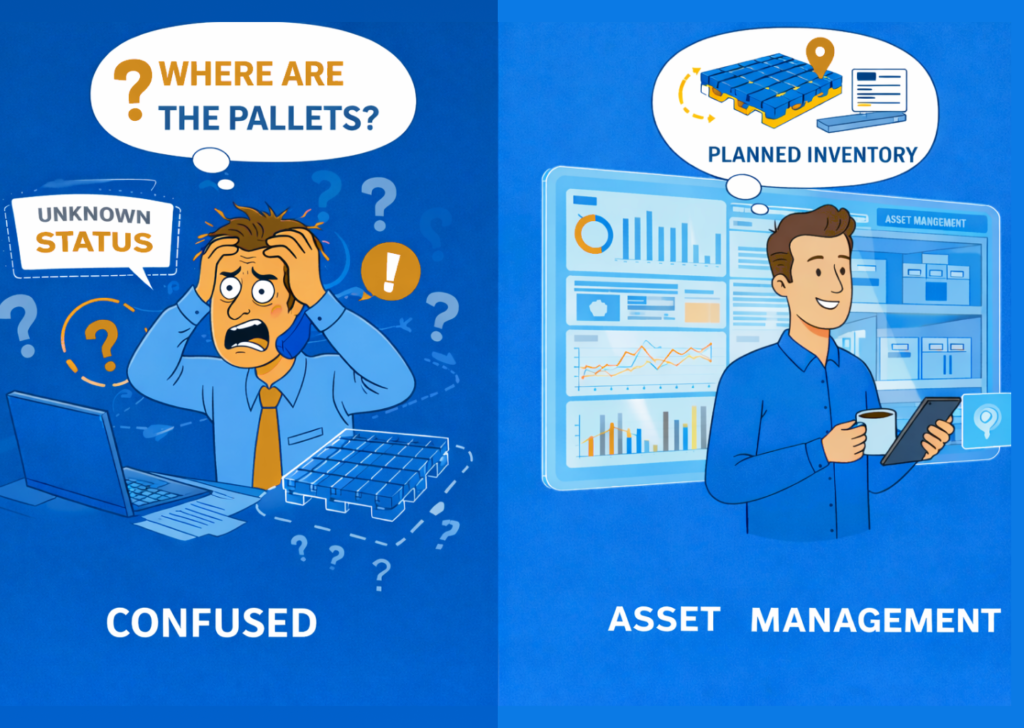

“Where are these pallets? They’re showing as available in the inventory register.”

If you work in warehousing, transport, or 3PL operations, you’ve heard versions of these conversations far too often.

They come up during shift handovers, monthly reviews, or uncomfortable calls with pallet pooling partners.

At times, you’d also hear the operational team getting riled up with emergency purchases of pallets because they can’t find enough for the next deliveries.

And almost always, these are treated as isolated incidents rather than symptoms of a much larger issue.

“Plastic pallets sit at the backbone of modern logistics.”

Their continuous movement is almost unavoidable across factories, warehouses, transport routes, and customer locations.

Yet despite their scale and importance, missing plastic pallets are still accepted as an operational nuisance that is just part of the business.

Across supply chains, returnable asset losses quietly accumulate through theft, misplacement, unverified handoffs, and prolonged dwell at customer or partner sites.

Plastic pallets theft is the most prominent one and has been documented for over several years now.

Most of these losses are never classified as theft. They simply fade out of the system.

That’s because no one knows they got stolen.

And the real challenge is not the absence of records. Inventory registers often show pallets as “available” long after they have effectively disappeared from circulation.

What’s missing is visibility into how plastic pallets move, where they stall, and where accountability breaks down. Without this visibility, logistics teams compensate by overbuying, writing off losses, and absorbing replacement costs as part of doing business.

This is where better asset visibility becomes critical. Asset tracking solutions that expose movement patterns, dwell time, and custody gaps bring silent losses into focus.

Let’s dig deeper into the problems of plastic pallets theft and how visibility makes it operationally easier to cut pallet losses and efficiently reuse pallets, the way they are meant to be.

The Huge Mess That Is Plastic Pallet Theft

Plastic pallet losses are not a marginal issue in logistics. They operate at scale, across regions, and across years. Industry estimates consistently point to millions of pallets going missing annually, translating into hundreds of millions of dollars in losses globally.

Large pallet pooling providers and logistics operators have documented that pallet theft and unexplained disappearance account for a significant share of their asset leakage every year.

What makes the problem harder to confront is how rarely these losses are treated as theft in the traditional sense. In many logistics networks, pallets do not vanish in dramatic incidents.

They are lost incrementally. A few pallets remain behind at a customer site. Some are diverted during transit.

Others are absorbed into informal reuse loops or secondary markets. Over time, these small leaks add up. Studies and industry reporting have shown that pallet-related losses alone cost supply chains hundreds of millions annually, with theft and non-return accounting for a major portion of that figure.

In the UK and parts of Europe, cargo and pallet-related theft has risen steadily over the past few years, driven by increased supply chain pressure, higher material costs, and more complex logistics flows.

Plastic pallets, in particular, have become attractive targets due to their durability, resale value, and ease of reuse. Yet even in regions where theft incidents are increasing, most missing plastic pallets are never logged as stolen. They simply stop circulating.

This is why inventory systems often tell a misleading story. Registers continue to show pallets as available or “in network,” even when they have effectively exited the system.

The absence of timely verification and visibility means losses surface weeks or months later, if at all. By then, responsibility gets blurred, and recovery is unlikely.

The scale of the problem is not defined by isolated theft events, but by a systemic invisibility and a prevalent mindset to treat these assets as consumables.

How Asset Visibility Actively Reduces Plastic Pallet Theft and Losses

Asset visibility reduces plastic pallet theft by removing ambiguity from the pallet lifecycle.

Most pallet losses persist because pallets are not viewed and continuously observable as assets; they are inferred through shipment events.

Asset visibility fixes this by shifting the management focus to pallets as well, going ahead from deducing its behavior just from inference.

At a practical level, pallet visibility starts with asset-level identification and continuity.

Each plastic pallet must be identifiable as a unique unit across its lifecycle, not just counted in bulk at dispatch and receipt.

This allows movement, dwell, and custody to be tracked independently of shipments. When pallets are removed from shipment-level assumptions, their loss patterns become much more obvious and can be observed sooner.

The next layer is dwell-time intelligence.

Silent losses happen mostly when pallets remain stationary beyond expected operational windows. Visibility systems that monitor dwell duration at customer sites, cross-docks, yards, and temporary storage locations expose these anomalies in near real time.

Extended dwell is the earliest indicator of pallet leakage, well before inventory discrepancies appear. Without dwell visibility, pallets transition from “delayed” to “missing” without any intervention window.

Custody tracking further sharpens accountability. Visibility across handoffs makes it possible to see not just where pallets are, but where should the responsibility lie.

When losses cluster around specific handoff points, routes, or partners, the issue shifts from network-wide variance to localized process failure. This enables corrective action such as revised return protocols, tighter receiving verification, or contractual enforcement, rather than blanket overbuying.

Visibility also enables historical pattern recognition, which is critical for addressing theft. Repeated deviations in circulation cycles, abnormal routing, or recurring dwell at the same locations indicate critical leakage points.

These patterns are invisible in static inventory reports but obvious when asset behavior is tracked consistently.

From an operational cost perspective, visibility changes the economics of loss management.

Early detection allows retrieval while pallets are still within reachable network boundaries. Late detection forces replacement. This distinction directly impacts margin.

When pallets are recovered instead of replaced, capital expenditure stabilizes and buffer stock requirements shrink. Over time, pallet pools can be sized based on actual circulation behavior rather than worst-case assumptions.

Finally, visibility integrates pallet management into broader logistics control. When asset movement and dwell data are connected to planning and execution systems, pallet availability becomes more predictable.

This reduces emergency procurement, avoids shipment delays caused by asset shortages, and prevents margin erosion caused by reactive decision-making.

In short, asset visibility does not eliminate plastic pallet theft by policing behavior.

It eliminates it by shortening detection cycles, restoring custody clarity, and converting silent losses into actionable exceptions before they become permanent.

How SensaTrak Enables Practical Visibility for Plastic Pallet Control

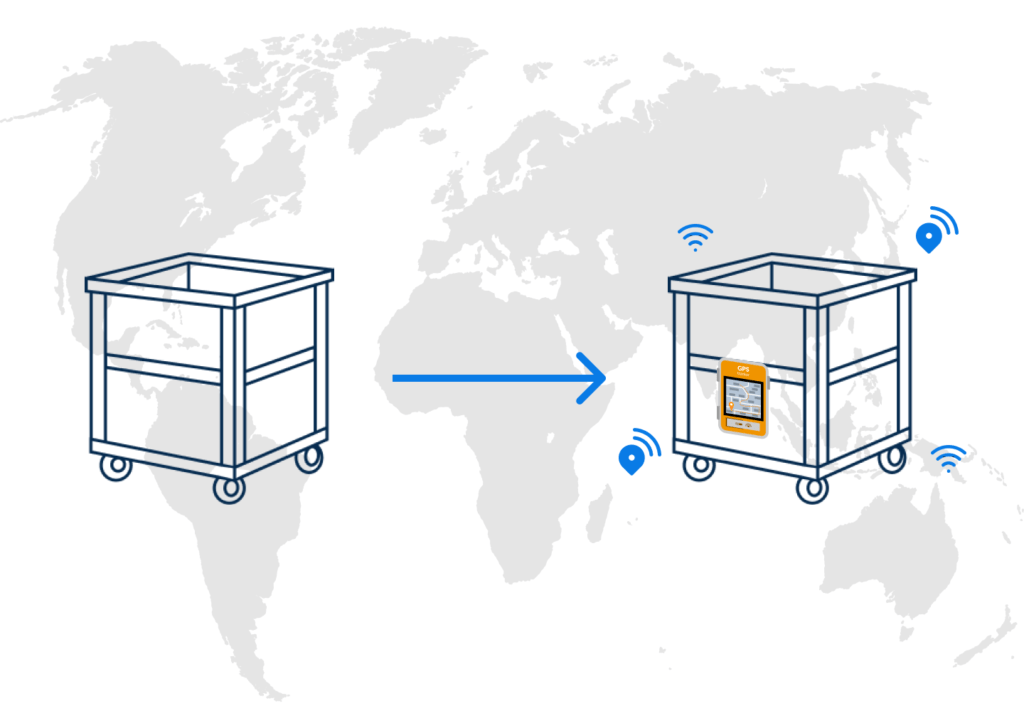

SensaTrak enables asset visibility by treating plastic pallets as your core valuable assets that need active monitoring.

At the asset level, SensaTrak instruments pallets so they remain observable across warehouses, yards, transit routes, and customer locations.

We extend visibility across movement, idle periods, and handoffs. Our trackers are also built to alert for any mishandling or any extra shock to the pallet that would render your asset damaged prematurely.

Our analytics platform emphasizes dwell and circulation intelligence. Pallet movement is continuously evaluated against expected operational timelines, making abnormal idle times and retention visible early.

We also restore accountability across custody transitions. By correlating asset movement with handoff points, the system makes it possible to identify where pallets consistently slow down, accumulate, or exit the network.

Most importantly, visibility is connected with operations through integration. Asset-level insights connect with existing logistics systems so pallet availability, risk, and recovery actions align with daily planning and execution workflows.

In practice, our monitoring approach reduces missing plastic pallets by enabling earlier intervention, better reuse discipline, and measurable reductions in returnable asset losses.

Explore our solution for:

Plastic Pallets | Roll Cages | Specialized Carriers