If you work in logistics and constantly juggle delayed deliveries, missing returnable assets, and service pressures, this will feel familiar.

Operating logistics networks today is hard enough. Doing it without full logistics visibility and while losing thousands of plastic pallets, roll cages, or reusable transport items every year makes it even harder.

Assets go missing, shipments get delayed, and teams are still expected to meet delivery commitments without disruption.

The operational challenges caused by poor visibility across logistics networks are significant and continue to grow. These challenges become even more complex when returnable assets enter the picture.

Unlike shipments that move once and exit the system, reusable transport items circulate continuously. They move in loops, sit idle for long periods, pass through uncontrolled environments, and change custody multiple times across partners and locations.

This is where most logistics operations struggle.

And there is only one way to address it meaningfully: stronger logistics visibility.

What Is Logistics Visibility?

Logistics visibility is the ability to track and monitor where assets, shipments, and equipment are, what is happening to them, how they are being handled, where they were last seen, why they are delayed, and what impact those delays have on operations.

Logistics teams today are under constant pressure to understand not just where goods and assets are located, but how operations are actually performing across warehouses, yards, transport routes, and customer locations. Visibility is no longer about tracking movement alone. It is about understanding behavior.

For logistics visibility to be effective, especially for RTIs such as plastic pallets, roll cages, crates, and specialized carriers, simple location tracking is not enough. Strong visibility requires insight into asset state, dwell behavior, handoff efficiency, and exception patterns over time.

Because returnable assets circulate repeatedly through the network, they are often responsible for more operational disruption than one-time shipments. When visibility is weak, these assets silently accumulate delays, losses, and inefficiencies that directly affect service levels and customer experience.

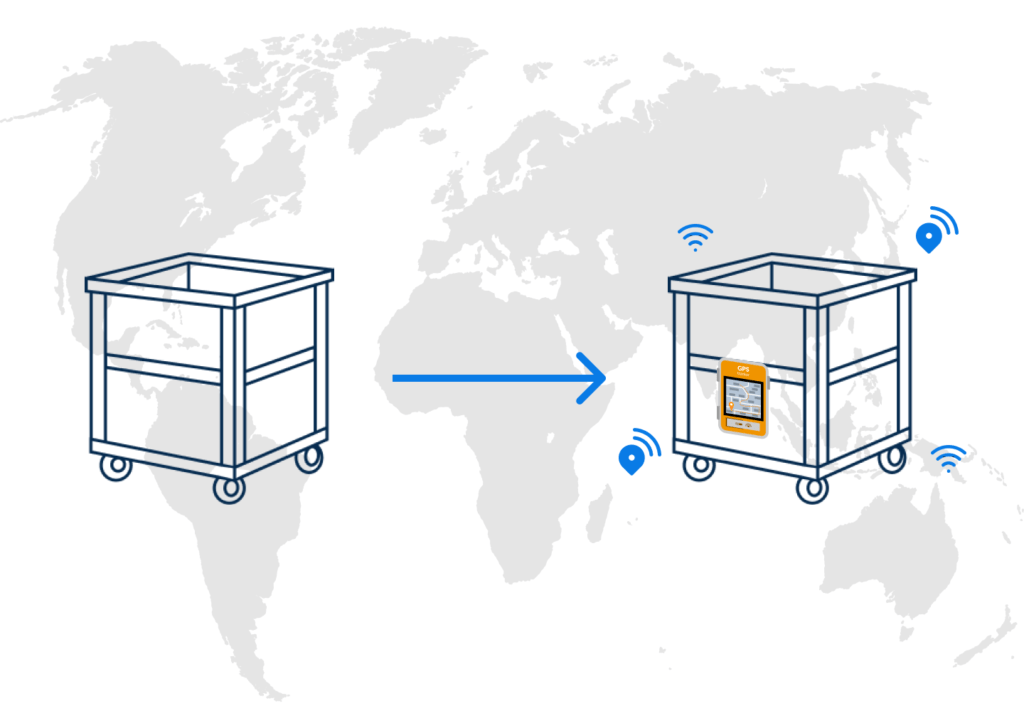

This blog explores why vanilla GPS-based location tracking falls short for modern logistics operations and why stronger logistics visibility, enabled through platforms like SensaTrak, is essential for managing returnable assets effectively.

Why Plain Location Tracking Is an Outdated Way to Run Modern Logistics

For decades, logistics visibility (and any logistics visibility platform) has leaned heavily on one idea: location tracking. GPS trackers became the default tool for understanding movement across supply chains, and for a long time, this approach was considered sufficient.

Knowing where a shipment or asset was last seen helped teams confirm movement, estimate arrival, and respond to obvious delays.

This model no longer works today

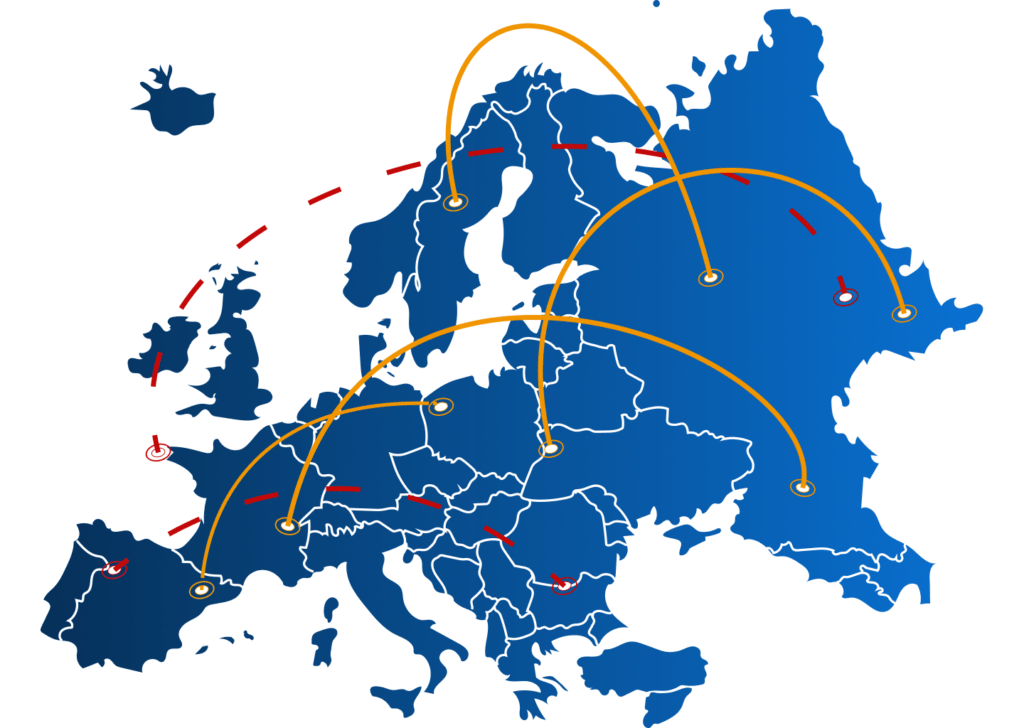

GPS-based asset tracking tools were designed primarily for outdoor, point-to-point movement. They work reasonably well when assets are in-transit across open routes. But modern logistics operations do not operate only on highways.

Returnable transport items move in and out of warehouses, yards, production facilities, customer locations, and temporary storage areas. Many of these environments limit GPS accuracy or block signals entirely. As a result, location data becomes intermittent, delayed, or incomplete at precisely the points where operational visibility matters most.

Even when GPS location is available, it tells only one narrow story.

Location tracking confirms where an asset was detected, but it says nothing about what is happening to that asset.

It does not explain whether a plastic pallet is idle, damaged, delayed due to a handoff failure, or sitting unused beyond acceptable dwell thresholds. For reusable transport items that circulate continuously, this lack of context makes it difficult to distinguish normal movement from emerging operational risk.

This limitation has broader consequences.

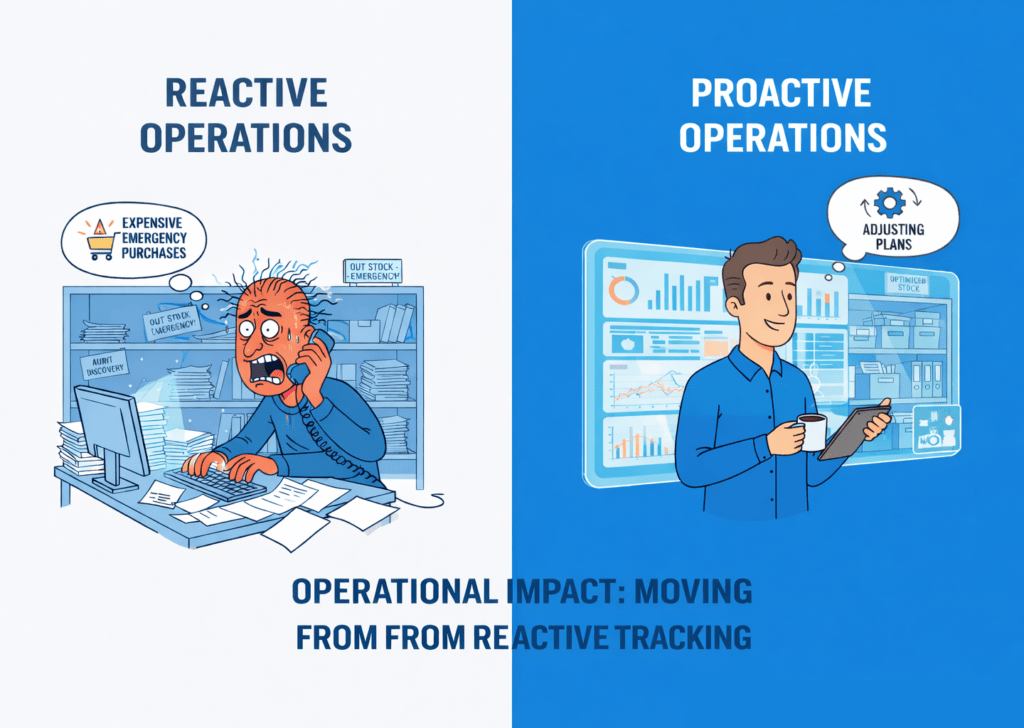

When logistics teams rely only on location data, they are left to infer asset condition, usage, and responsibility through manual checks and assumptions. These gaps increase the likelihood of SLA breaches, as delays go unnoticed until they impact delivery commitments.

They also create sustainability and compliance risks, as teams struggle to prove asset reuse, lifecycle efficiency, and loss reduction under tightening regulatory scrutiny.

In effect, plain location tracking provides visibility in isolation. It offers a data point, not an understanding. As logistics networks become more complex and compliance expectations rise, relying on GPS-only tracking leaves teams with incomplete information and growing exposure across cost, service, and sustainability outcomes.

What Stronger RTI Data and Insights Actually Look Like in Practice

Consider a mid-sized logistics operation managing ~20,000 assets – a mix of plastic pallets and roll cages – across multiple warehouses, transport routes, and customer locations.

On paper and in their inventory management systems, the asset count looks healthy.

But, in reality, the Operations Head faces this on a regular basis:

shortages at some sites, overflows at others, assets gone missing even when the last location shows updated, assets lost in-transit, assets that are available on the location but damaged due to mishandling and eventually emergency purchases to keep shipments moving.

With more insights on the RTIs, this changes dramatically.

Instead of seeing only the last known location of an RTI, the operations team can view

- how long does each asset spend at any particular location,

- how frequently do they circulate through the network,

- at which locations dwell times are consistently higher,

- how is an asset being handled, who handled it last,

- which route/network point has a history of missing assets

And much more than this.

If your assets are stuck at customer locations, yards, or partner facilities, they can be seen in real-time rather than being discovered weeks later during audits.

Stronger data and insights also bring more accountability into your operations.

You can now easily track and monitor every handoff that occurred in the entire chain. That easily gives you clear proof of who handled the assets and how they were handled.

From a logistics visibility standpoint, this depth of insight has tremendous impact:

- Planning becomes more accurate because asset availability is based on actual behavior, not just assumptions.

- SLA risks are identified earlier because delays form gradually through extended dwell and missed handoffs, not suddenly at the point of failure.

- Sustainability reporting improves because reuse, lifecycle duration, and loss reduction can be demonstrated with evidence rather than estimates.

Here, stronger logistics visibility, essentially visibility into the lifeline of logistics – the returnable assets – is not about more data.

It is about getting the right data, connected over time, giving your teams the ability to understand and influence how returnable assets move, stop, and perform across the network.

Logistics Visibility Platform That Changes This

Strong logistics visibility is no longer about knowing where assets were last seen.

For returnable transport items, it is about understanding how assets behave across the network, where friction builds up, and which patterns quietly drive cost, delays, and risk.

As logistics operations grow more complex and compliance expectations rise, teams that rely only on plain location tracking will continue to operate reactively.

The only efficient way to manage logistics operations today is to aim for end-to-end logistics and supply chain visibility. And that is facilitated by good asset tracking solutions for your returnable assets.

Modern logistics visibility software and logistics visibility platforms such as SensaTrak, which focus on asset behavior and lifecycle visibility rather than location alone, reflect this shift toward more resilient, performance-driven logistics operations.

Explore how we use tamper-safe trackers, AI & observability led analytics and seamless integration capabilities to bridge the information and visibility gap for your RTI fleet.