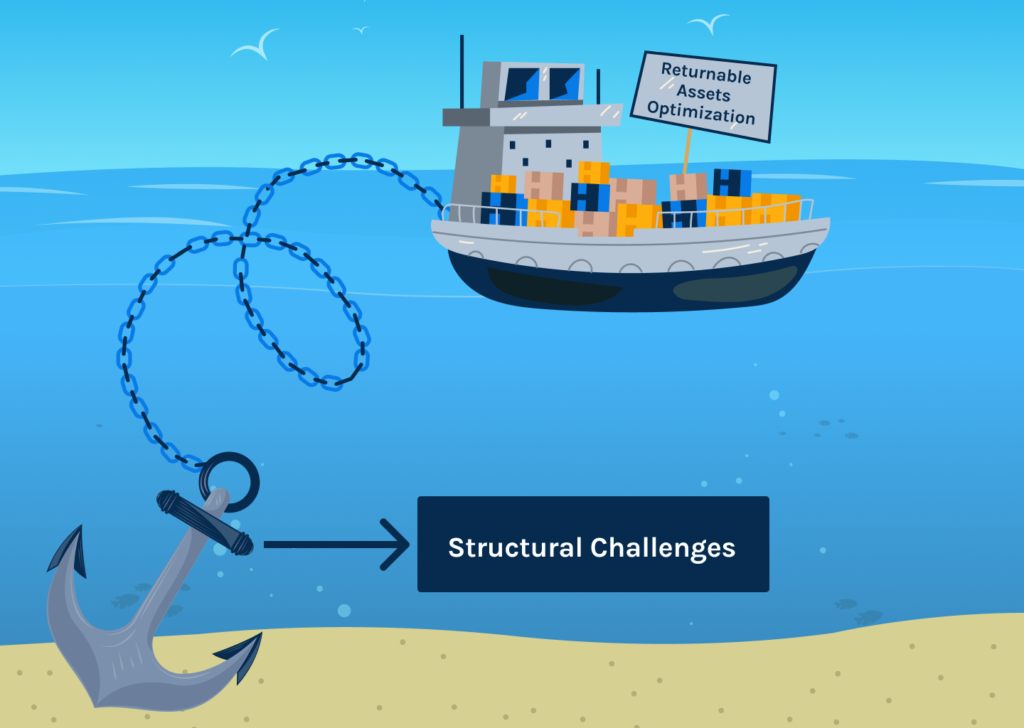

As the logistics industry adapts to an increasingly data-driven and sustainability-conscious world, the need for advanced returnable asset management solutions has never been more urgent. Companies of all sizes are realizing that the traditional methods of tracking and managing their reusable assets are no longer sufficient. In a world where visibility, efficiency, and sustainability are paramount, asset tracking systems have evolved far beyond simple location identification.

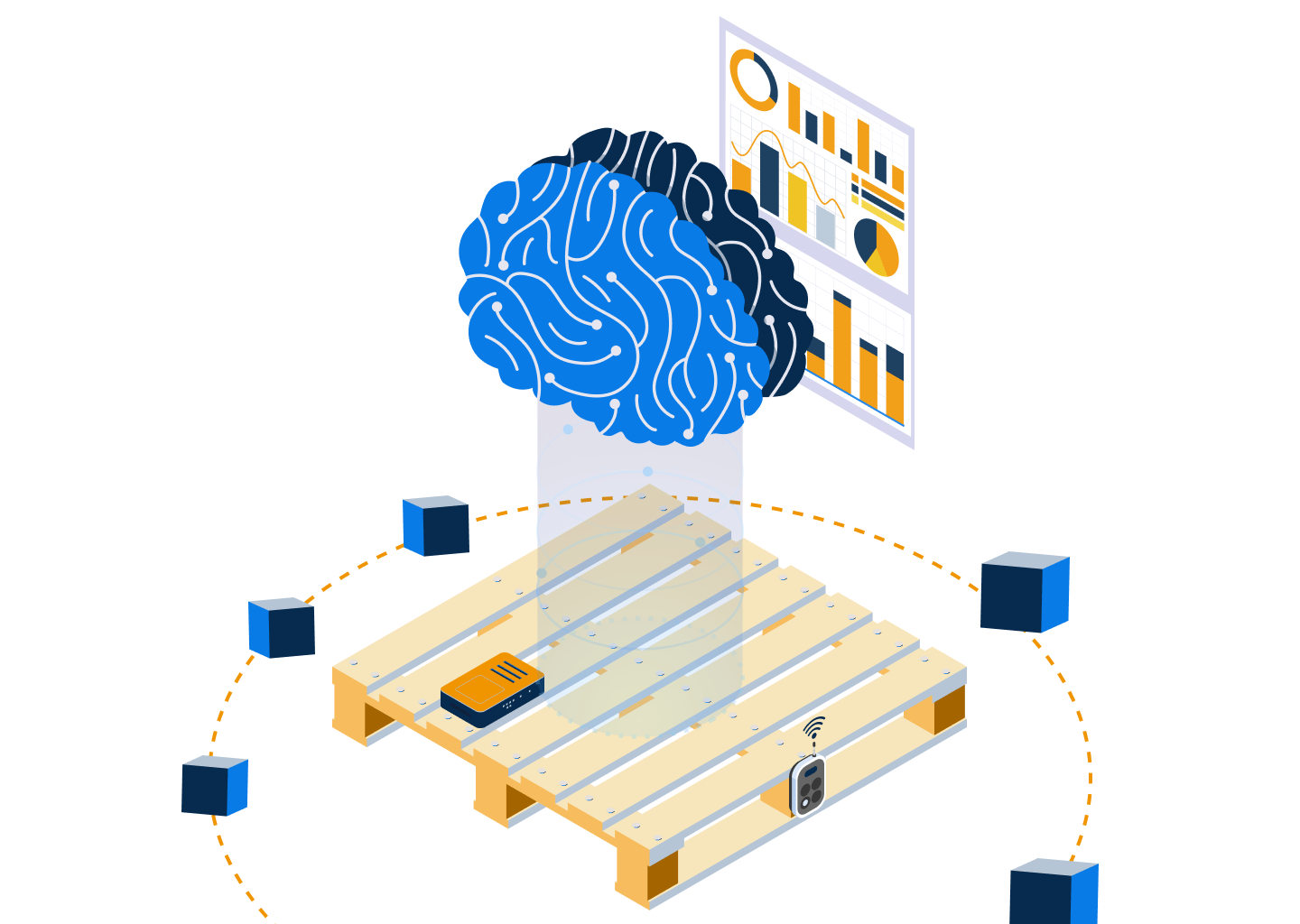

Looking ahead to 2025 and beyond, the landscape of asset tracking tools is set to undergo a seismic shift. This shift is driven by technological advancements like the Internet of Things (IoT), predictive analytics, and machine learning. With more assets being reused and shared across supply chains, businesses require not just basic tracking, but intelligent systems that can provide predictive maintenance, optimize rotation, and reduce downtime across the asset lifecycle. These technologies will not only make reusable asset management more efficient but will also help companies meet their sustainability goals.

In this blog, we will explore the key technology trends shaping asset management for 2025 and beyond. From the integration of IoT and cloud-based platforms to the adoption of AI and blockchain for traceability and predictive insights, these technologies are changing the way businesses approach asset management.

By the end of this article, you’ll understand why asset tracking systems are now essential, what trends are shaping the future, and how companies can use them to optimize their operations and meet their ESG commitments.

Trends In Returnable Asset Management Technology for 2025 and Beyond

IoT and Edge Computing: The Backbone of Modern Returnable Asset Management

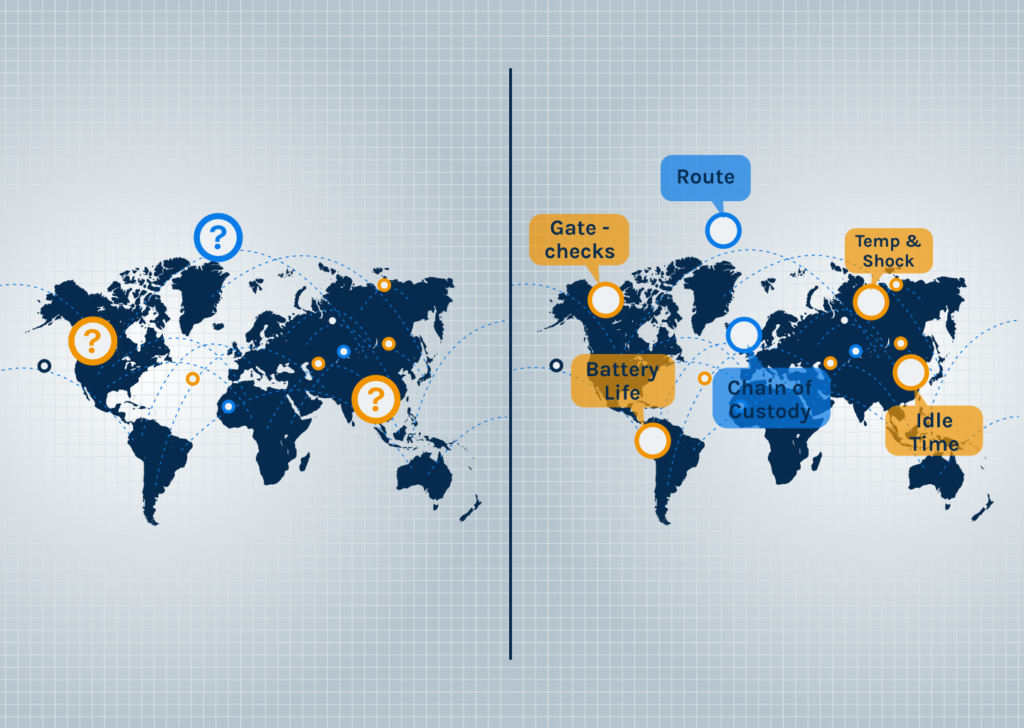

The integration of IoT technology with asset tracking systems is accelerating. IoT sensors, such as RFID, GPS, and BLE, allow companies to track reusable assets in real time, no matter where they are in the supply chain. The next frontier, however, is edge computing, which processes data closer to the asset itself, reducing the latency of information transmission. This is especially important for industries that rely on fast decision-making and where real-time data is crucial.

To give more context, almost 85% of the supply chain & logistics players in a 2023 survey by Eseye, reported to have planned an increase of their IoT investments in the coming years. This highlights significant confidence in what IoT technology can achieve for the logistics and supply chain sector.

Real-world applications:

- Food and pharmaceuticals: Tracking temperature-sensitive assets, such as refrigerated containers, ensures products remain within required conditions throughout the supply chain.

- Manufacturing: IoT sensors on parts and equipment provide real-time condition reports, helping businesses manage inventory and reduce unplanned downtime.

Predictive Analytics and AI: A Shift from Reactive to Proactive Reusable Asset Management

The role of predictive analytics is becoming central to asset management systems. By analyzing historical data, AI models can predict when assets will need maintenance, repairs, or even replacement. Predictive capabilities take asset management from a reactive approach, where businesses address problems after they arise, to a proactive one, where problems are anticipated and mitigated before they disrupt operations.

Drawing parallels to returnable assets management and predictive analytics is the computer vision AI systems that is helping with extensive predictive maintenance in logistics space. DHL’s 2023 Trend Report on AI-Driven Computer Vision highlighted that AI and predictive maintenance technologies could reduce maintenance costs by 25%, unplanned downtime by 35% and give 10x return on initial technology investment.

The ability to anticipate failures based on usage patterns, environmental factors, and asset wear helps companies optimize the lifecycle of reusable assets and prevent costly downtime.

For example, AI-driven insights can inform businesses about when an asset is nearing the end of its useful life or when it’s likely to encounter issues such as wear and tear. By catching these problems early, businesses can optimize their fleet’s performance and avoid expensive emergency repairs.

Cloud Platforms: The Hub for Asset Tracking and Data Management

As companies move toward cloud-based solutions, asset management platforms are evolving to integrate data from multiple sources, such as ERP, WMS, and asset tracking tools. Cloud-based platforms allow businesses to centralize asset tracking systems and manage their fleets across different geographies and logistics operations seamlessly. The cloud also supports scalability, enabling companies to track reusable assets of any size, from small fleets to large, global operations.

Cloud-based asset management systems are expected to see tremendous growth in adoption in the coming years. Specifically, for logistics & supply chains where the data & analytics needs are so immense. Companies that embrace cloud platforms will gain a competitive edge by integrating real-time data, improving visibility, and making faster, data-driven decisions.

Cloud platforms also facilitate the integration of reusable asset management data with sustainability reporting tools, allowing businesses to meet regulatory and ESG reporting requirements efficiently. With real-time data available across all systems, businesses can generate accurate reports on asset usage, waste reduction, and emissions savings — all key metrics for sustainability.

Blockchain: Securing Asset Provenance and Improving Transparency

With supply chains growing in complexity, ensuring the provenance of assets is becoming a major priority. Blockchain provides a secure, immutable ledger that records every transaction in the asset’s lifecycle. This technology is particularly useful for businesses that need to prove the authenticity and history of their reusable assets for compliance or regulatory reasons.

Accenture’s 2022 report on blockchain in logistics highlighted its potential to streamline supply chain processes by creating a transparent and verifiable trail for asset usage.

Blockchain can help track reusable assets through every stage – from dispatch to delivery and return – providing a single source of truth that is accessible to all stakeholders.

For example, companies in pharmaceuticals can use blockchain to ensure that temperature-sensitive products are always tracked through the cold chain, guaranteeing the product’s integrity for audits or regulatory reporting.

Looking Ahead: The Future of Asset Management

As we move towards the end of 2025, the integration of asset tracking technology with AI, cloud platforms, and blockchain will provide an even more more complete picture of reusable asset management.

The future of returnable asset management will no longer be about tracking where assets are; it will be about leveraging data to maximize their use, reduce costs, and support sustainability goals.

Companies adopting these technologies now will have a significant advantage as they streamline their supply chain operations, improve asset performance, and meet increasingly stringent sustainability targets.

For mid-sized businesses, asset tracking tools that offer predictive insights, data integration, and easy scalability will be essential to staying competitive in a rapidly evolving market.