If you’ve dealt with reusable assets and their management before, you already know that the options for tracking technology aren’t scarce – they’re overwhelming but far from a perfect choice.

Managing reusable assets has evolved from a simple logistical task to a complex ecosystem of connectivity, visibility, and data interpretation. The challenge is no longer about whether you can track your assets, but how accurately and under what conditions you can do it.

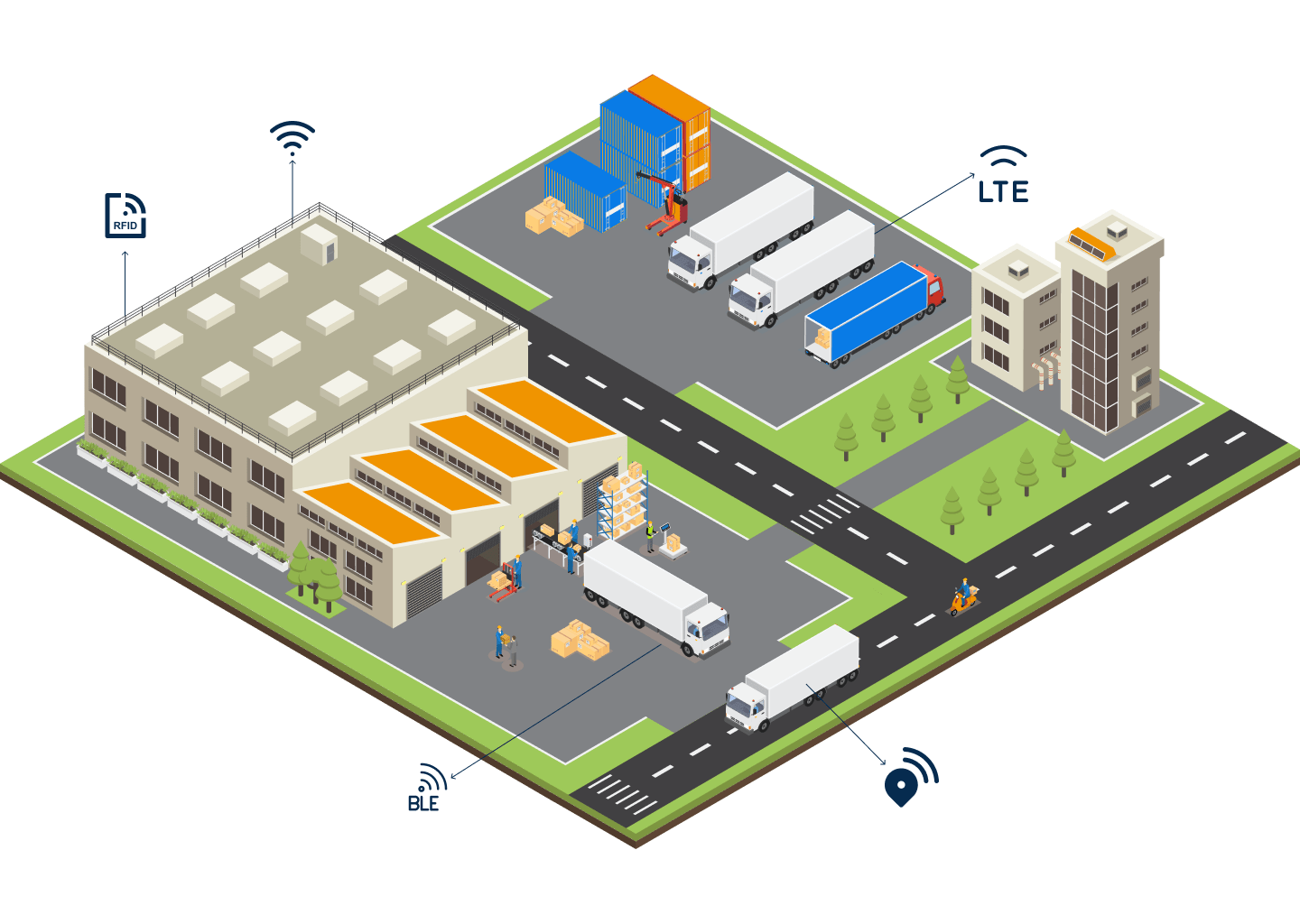

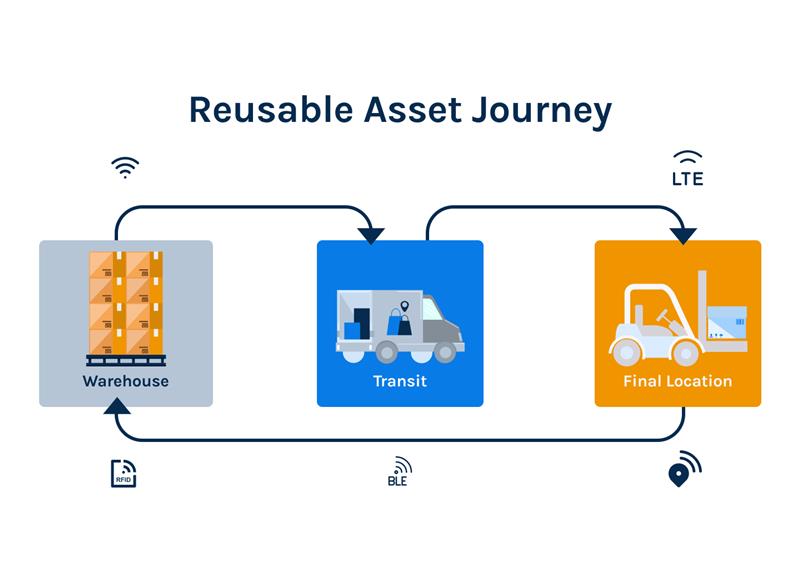

Each of the technologies used for tracking for reusable assets, whether RFID, BLE, GPS, or LTE-based, behaves differently depending on where it’s deployed.

Some, like BLE beacons and RFID, excel in high-density indoor environments like warehouses and cold storage facilities, where quick scans and proximity matter more than distance. Others, like gps trackers thrive outdoors, tracing assets that move across geographies, often through conditions where power consumption, coverage, and signal reliability become limiting factors.

The real complexity lies in matching the right tool to the right task. RFID provides low-cost, high-volume identification but struggles beyond fixed gates. BLE offers continuous indoor visibility but trades off battery life and range. GPS brings unmatched outdoor accuracy but at the expense of power. LTE and NB-IoT connect everything together — yet even these networks face coverage and cost trade-offs.

The result is a fragmented landscape where every technology solves one part of the problem but rarely the whole. That’s why the future of tracking for reusable assets depends not on picking one technology over another, but on combining them intelligently – creating a unified asset tracking system that delivers uninterrupted visibility from warehouse to delivery, indoors and outdoors alike.

What Each Technology Does Best (and Where the Trade-offs Lie)

Choosing the right tracking technology for returnables could be a very strategic choice for your business and operational flow. Each option excels in a specific setting, with its own cost, coverage, and power trade-offs.

RFID is still the fastest, most affordable way to identify assets in bulk. Passive tags cost cents, need no batteries, and scan hundreds of items in seconds. But range is limited, and once assets leave the gate, visibility stops.

BLE fills that gap indoors. Active beacons send live proximity and condition data, offering room-level accuracy for a few years on a small battery. The trade-off: denser beacon networks mean higher maintenance.

GPS/LPGPS provides outdoor precision – knowing where assets go, not just when they move. It’s ideal for containers and high value returnable assets, but needs power management to avoid battery drain.

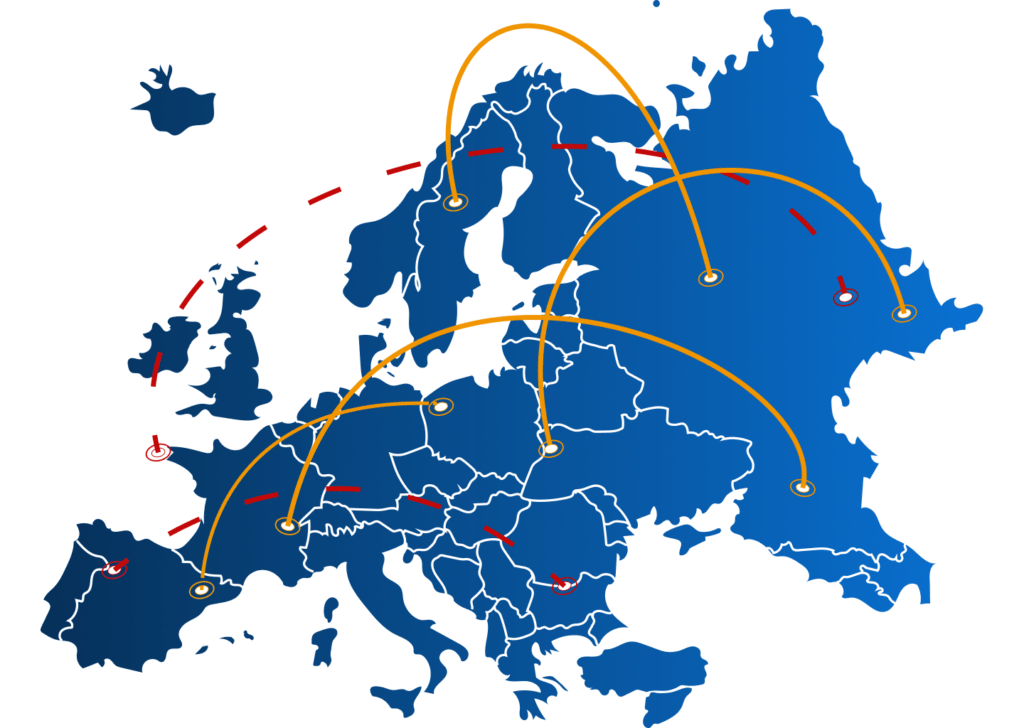

LTE-M/NB-IoT keeps all layers connected, transmitting small data bursts efficiently across long distances. Coverage and roaming vary by region, but LTE-M offers global mobility, while NB-IoT favors low-cost domestic coverage.

Wi-Fi fallback bridges indoor–outdoor handoffs by using nearby network IDs to maintain continuity where GPS can’t.

The key lies in combining these layers smartly. RFID for event logging, BLE for movement, GPS trackers for route & location, LTE for communication – each complements the other. When used together, they balance precision, cost, and battery life, creating an asset tracking system that’s both scalable and sustainable.

Why Multi-Technology Tracking for Reusable Assets Matters A Lot

Returnable assets don’t move in straight lines. They pass through warehouses, transit hubs, and distribution networks that mix open roads with signal-dense environments. A single tracking layer can’t capture that complexity — and when visibility breaks, efficiency suffers.

RFID alone logs only that an asset left a site. BLE alone shows proximity, not the full route. GPS trackers alone give coordinates, but misses handling context. The result is blind spots that slow rotation, increase losses, and make sustainability reporting harder to substantiate.

There are multiple recent case studies which highlight that the strongest results come from hybrid deployments. A study in 2020 published in Science Direct evaluated multiple tracking technologies – including RFID, BLE, Wi-Fi, and hybrid IoT systems – across industrial logistics environments.

The findings showed that while each technology offers distinct advantages, none alone can guarantee uninterrupted asset visibility. RFID performs best for event detection, BLE for proximity sensing, and GPS or Wi-Fi for spatial continuity, but their true value emerges when used together.

The study concludes that hybrid, multi-layer tracking architectures provide significantly higher accuracy and operational reliability, making them the most practical approach for complex, real-world logistics operations.

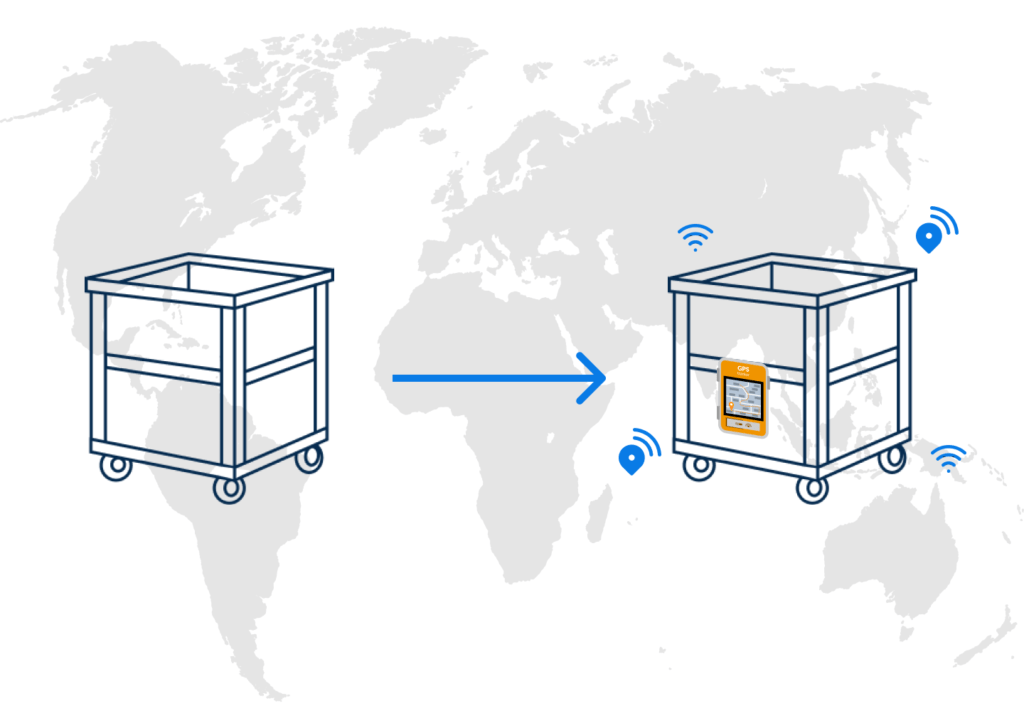

How SensaTrak Combines LTE, Wi-Fi, BLE, and LPGPS for Continuous Connectivity

At its core, SensaTrak was engineered to overcome one of logistics’ oldest challenges — visibility gaps. Assets constantly move between connectivity zones: from Wi-Fi-covered depots to BLE-enabled warehouses to highways where only LTE and LPGPS signals can function reliably. Most systems lose track somewhere in between. SensaTrak doesn’t.

Its trackers are built on a multi-layer connectivity model, where each signal plays a distinct but complementary role.

- BLE provides continuous indoor awareness — capturing movement, dwell time, and condition data such as temperature or shock.

- Wi-Fi bridges transition zones, identifying nearby networks to maintain positional continuity as assets move through covered docks or storage areas.

- LPGPS activates in open environments, recording precise outdoor location and route data while conserving power through event-based wake cycles.

- LTE-M/NB-IoT connects all of it — transmitting data packets efficiently from any geography, ensuring the cloud always has the latest verified asset state.

What makes SensaTrak’s system exceptional is not just this hardware mix, but how intelligently it orchestrates them. The platform’s firmware automatically selects the most efficient signal based on context – BLE indoors, LPGPS outdoors, Wi-Fi in handoff zones, LTE for transmission.

This adaptive behavior reduces battery consumption, minimizes redundant data, and ensures assets remain visible throughout their lifecycle.